Power Trowel Blade Guide: Types, Angles, and Installation

Power trowel blades play a critical role in the concrete finishing process, determining the quality and smoothness of the final surface. Selecting the right blade and understanding its installation and angle are essential for achieving efficient and effective results.

Whether it’s a finish blade for the final pass or a float blade for initial leveling, the choice of blade can significantly impact the outcome of the concrete finishing. In this post, we will explore the different types of power trowel blades, their angles, and the proper installation techniques to help you maximize the efficiency and effectiveness of your concrete finishing projects.

Power trowel blade:

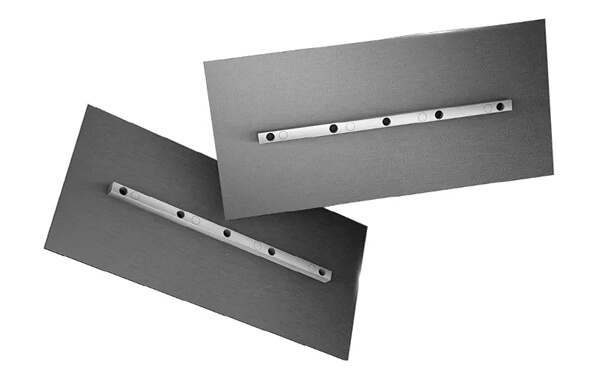

- A power trowel blade is a flat, metal disc with a curved edge that is attached to the rotating arms of a power trowel machine.

- It is designed to flatten, level, and smooth the surface of freshly poured concrete.

Importance of selecting the right blade for efficient concrete finishes

- The selection of the appropriate power trowel blade is critical to achieving efficient and effective concrete finishing.

- Different types of blades are available to suit various concrete applications, such as floating, finishing, or burnishing.

- Choosing the right blade ensures optimal performance, improved productivity, and a high-quality finish.

Contents

Types of Power Trowel Blades

A. Finish Blades

- Description and purpose:

- Finish blades are specifically designed for achieving a smooth and flat finish on concrete surfaces.

- They have a fine-grit surface that helps to refine the texture and eliminate imperfections.

- Finish blades are commonly used in the final finishing passes to achieve a polished and professional look on the concrete.

- Smooth and flat finish:

- The primary goal of finish blades is to create a smooth and flat surface on the concrete.

- These blades effectively remove any minor imperfections and unevenness, resulting in a visually appealing finish.

- Ideal for final finishing passes:

- Finish blades are typically used in the later stages of the concrete troweling process.

- They are ideal for the final finishing passes where the goal is to achieve the desired surface texture and smoothness.

B. Combination Blades

- Description and purpose:

- Combination blades offer a versatile solution as they combine floating and finishing capabilities in a single blade.

- They are designed to be adaptable for various stages of concrete finishing, providing convenience and efficiency.

- Combine floating and finishing capabilities:

- Combination blades have a dual-purpose design that allows for both floating and finishing of the concrete.

- They can effectively level the surface during the floating stage and refine the texture during the finishing stage.

- Versatile for various concrete finishing stages:

- Combination blades are suitable for different stages of the concrete finishing process.

- They provide flexibility and convenience, allowing users to transition seamlessly from floating to finishing without changing blades.

C. Float Blades

- Description and purpose:

- Float blades are primarily used for the initial concrete floating process.

- They are designed to level the surface and remove excess water from the freshly poured concrete.

- Initial concrete floating to level and remove imperfections:

- Float blades help to level the surface by pushing down the aggregate and bringing the cream to the surface.

- They also aid in removing any imperfections or high spots that may be present in the concrete.

- Prepares the surface for subsequent finishing passes:

- Float blades play a crucial role in preparing the concrete surface for subsequent finishing passes.

- By leveling the surface and addressing imperfections, they create a more even and uniform base for the final finishing steps.

Blade Angle and Its Significance

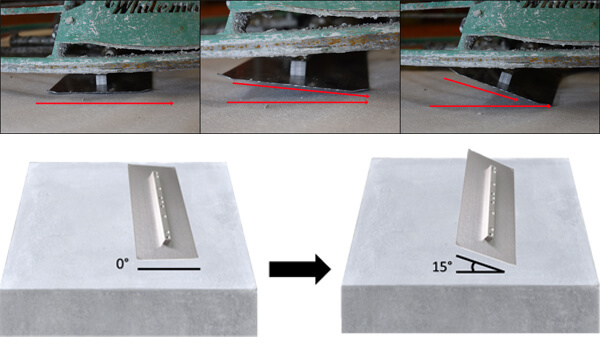

A. Importance of blade angle:

- Blade angle plays a critical role in the efficiency and effectiveness of concrete finishing with a power trowel.

- It determines the contact between the blade and the concrete surface, affecting the troweling process and the final result.

B. Effects of different angles on concrete finishing:

- A flatter blade angle (lower pitch) allows for a more aggressive troweling action, removing imperfections and leveling the surface quickly.

- A steeper blade angle (higher pitch) provides a smoother finishing action, refining the surface texture and creating a polished look.

C. Factors influencing the selection of blade angle:

- Concrete consistency and hardness: Softer concrete may require a flatter blade angle for more effective leveling, while harder concrete may benefit from a steeper angle for achieving a smooth finish.

- Desired surface texture: Different projects may have specific requirements for the surface texture, which can influence the choice of blade angle.

- Operator skill and experience: The operator’s familiarity with different blade angles and their ability to control the trowel can influence the selection.

Installation of Power Trowel Blades

A. Preparation:

- Safety measures:

- Wear appropriate personal protective equipment (PPE), including gloves and safety goggles, to protect against potential hazards.

- Ensure the power trowel is turned off and the engine/motor is completely shut down before starting the blade installation process.

- Equipment required:

- Gather the necessary tools, such as a wrench or socket set, for removing and installing the blades.

B. Removal of old blades:

- Steps to remove worn-out or damaged blades:

- Locate the blade mounting bolts or fasteners on the power trowel.

- Use the appropriate tool to loosen and remove the bolts, carefully taking note of their original positions.

- Slide the old blades off the mounting arms or disc.

C. Installation of new blades:

- Alignment and positioning:

- Position the new blades onto the mounting arms or disc, aligning them with the original bolt holes.

- Ensure the blades are facing the correct direction based on the manufacturer’s instructions.

- Securing the blades:

- Insert the bolts through the blade mounting holes and tighten them securely.

- Follow the recommended torque specifications provided by the manufacturer to ensure proper blade installation.

D. Safety considerations during blade installation:

- Always handle the blades with caution, as they can be sharp and cause injuries.

- Double-check that the blades are securely fastened to prevent any accidents during operation.

- Regularly inspect the blades for signs of wear or damage and replace them as needed to maintain optimal performance and safety.

Conclusions

In conclusion, selecting the right power trowel blade and ensuring proper installation are crucial for achieving efficient and effective concrete finishing. The different types of blades, such as finish blades, combination blades, and float blades, serve specific purposes in the concrete finishing process.

Additionally, considering the blade angle and following proper installation procedures are essential for optimal results.

By paying attention to these factors, users can enhance their concrete finishing capabilities and achieve high-quality, professional results.

Leave A Comment