Tamping Rammers 101: How They Work and Their Advantages

Tamping rammers are machines that are used to compress various types of dirt in various building circumstances. It has an effect on the soil surface, making it level and compact.

The vibratory tamping rammer machine is a lightweight and portable compaction equipment that compacts soil by vibration.

Contents

How a Tamping Rammer Works

Principles of operation

The vibratory tamping rammer machine is a lightweight and portable compaction equipment that compacts soil by vibration. Its rounded shape and simple operation let it to reach into small corners, making it ideal for usage in difficult-to-reach areas. These devices are powered by gasoline, diesel, or electric engines.

Tamping rammers focus greater emphasis on specific spots due to direct compaction, rather than vibrating the soil in situ. Furthermore, their more elegant shape enables them to penetrate locations where the vibrating plate compactor may be unable to reach.

Soils suitable for tamping rammer

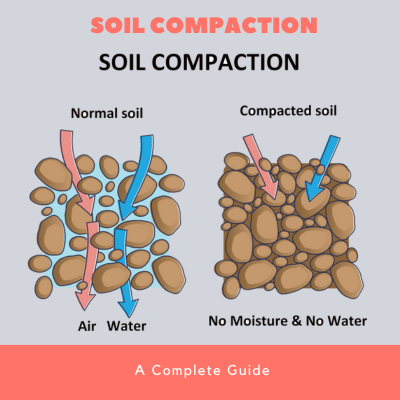

The rammer compacts the earth by impacting it. They exert a significant compressive force on the earth, squeezing out any water and air.

Tamping rammers, also known as jump jacks or jack rammers, work well in soils with humidity levels as low as 13%. When it comes to soil types, they should be employed with cohesive soils. Clay or any soil with a high clay percentage is referred to as cohesive soil. This dirt adheres tightly, especially when moist. When dried, cohesive soil is tough to break and will not chip.

When operating a rammer on gravel or asphalt, avoid damaging the equipment. Furthermore, the rammer is unsuitable for granular materials. If you use one on such soil, you will just dig a hole.

Types of rammers

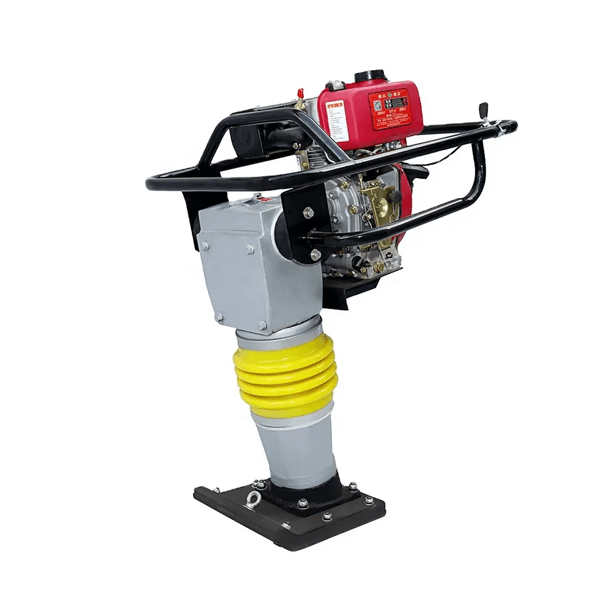

Gasoline tamping rammer

The cylinder is built on the two-stroke internal combustion engine concept, with two upper and lower pistons; the top piston is an internal combustion piston, while the lower piston is a buffer piston. The lower section of the cylinder is equipped with a rammer with an inclined bottom surface, causing the cylinder’s vertical axis to be inclined forward.

The upper piston rod protrudes from a through-hole in the centre of the cylinder head cover, while the lower piston rod protrudes from the cylinder’s lower end and is merged with the rammer. Spring tensions the cylinder and the rammer, and handrails are supplied to manage the rammer.

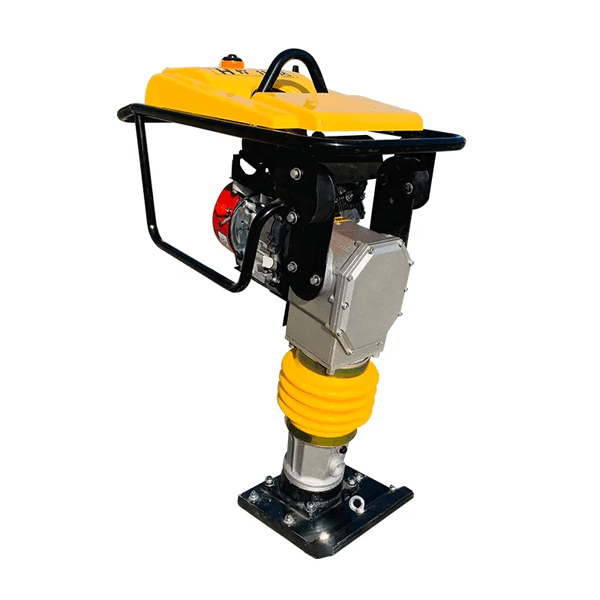

Motor tamping rammer

It is built on the rotational inertia force concept and consists of a rammer, a ram frame, an eccentric block, a pulley, and a motor.

The motor and gearbox are positioned on the skid base, and the ram frame’s rear end is pivoted with the transmission shaft. The ram frame may swing up and down along this axis due to the eccentric block’s centrifugal force.

Factors to Consider When Choosing a Rammer

Size and weight

The smaller and lighter it is, the more it is portable. If it is with a travel dolly that would be an added benefit. It’s possible that where you park your truck and where you need to condense aren’t as near as you believe. Have you ever attempted dragging a rammer through the dirt to get to your trench? It’s not easy. Even with two people carrying it, trying to move these devices over any distance is not ideal. This is when a travel dolly comes in handy.

Being able to attach a lightweight dolly to a rammer and transport it from one location to another requires less manpower, is easier, and is faster.

Engine type

Usually, motor-powered rammers are a quieter option. However, with them, you need to drag around the cables. Diesel-powered rammers are noisier but they are with no strings attached.

Hearing protection may not appear to be a huge problem, but it is, especially when working with large, noisy gear like a rammer. When harm is done, it is irrevocable, therefore proceed with caution the first time to avoid any loss.

Impact force

Impact force is one of the major factors deciding the type of rammer. Usually, for clayey sands, you would need a much heavier rammer.

Handle with adjustable height

There is nothing worse than utilizing equipment that was not built for you. When it comes to tamping rammers, it’s especially tough to perform a decent job compacting if the handle height of your machine isn’t comfortable for you to operate.

Certain rammers on the market include adjustable handles, allowing the user to fine-tune the machine to his or her tastes prior to lengthy usage. This is a challenging feature to include since it is not something you can just add to your buy if the product was not designed with individuals of varying heights in mind.

Maintenance and Safety Considerations

Regular maintenance

- Make frequent visual checks to ensure that everything is in good working order.

- Check the gasoline and engine oil levels, as well as the fuel lines and fittings for leaks or cracks.

- Tighten all exterior hardware and ramming shoe hardware.

- Cover for a clean air cleaner.

- Using an air compressor, clean up the engine cooling fins.

- Clean and inspect the spark plug gap.

- Remove all filters.

- Remove the recoil starter and clean it.

- Replace the oil in the ramming system.

- Clean the engine muffler and exhaust port.

- Examine the lifting cable for signs of wear, injury, or misuse.

- Examine the fuel filter.

- Examine the gasoline and oil lines for damage and repair them if required.

- Regardless of evident wear, replace fuel and oil lines every two years.

Safety Tips

- Wear safety goggles or glasses, hearing protection, and safety shoes.

- Always keep your hands, feet, and loose clothes away from the rammer’s moving parts.

- When using a rammer, always use common sense and prudence.

- When not in use, always ensure that the rammer does not tip over, roll, slide, or tumble.

Conclusion

Tamping rammers are equipment that is used to compress various types of earth in a variety of construction situations. It has an effect on the soil surface, leveling and compacting it.

Tamping rammers, as opposed to vibrating the soil in place, place more attention on specific locations owing to direct compaction. They should be used with cohesive soils when it comes to soil types. They should be used with cohesive soils when it comes to soil types.

Leave A Comment