What is a Tamping Rammer Used For?

Technological advancements in the construction industry in the recent past have been tremendous. Tamping rammers are some of the commonly used inventions in small-scale and medium-scale construction projects.

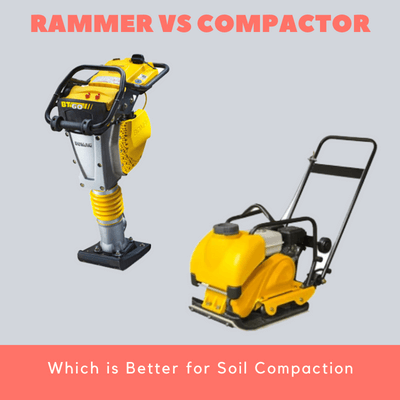

The tamping rammer uses are a vertical movement mechanism to compact material. It has a foot connected to the engine by a shaft that moves vertically to exert compaction force on the material. The shaft movement creates a tamping effect hence the name, tamping rammer.

Compaction is an essential process in construction and landscaping projects. Efficiency in these projects guarantees project durability and safety. Tamping rammers exert a higher compaction force over a large area. A higher compaction force facilitates deeper compaction for stable soil structures.

Operation of tamping rammers is done in overlapping passes; ensuring no spots are missed throughout the surface under compaction.

Contents

Main Uses of a Tamping Rammer

Soil Compaction

Soil compaction is the forceful packing of soil particles close to each other. The process involves applying a vertical force to the soil by physical or mechanical means. With this, the air particles and moisture are eliminated from the soil.

Foundations are a critical part of constructed buildings; they transfer the entire load of the building to the ground. Having a stable foundation prevents collapse of the structure due to sliding or settling. When foundation soils settle under structural weight, they alter load distribution in the building.

As a result, structural members such as columns and beams collapse. Insufficient compaction can cause soil particles to slide horizontally in presence of water and air particles. This leads to sliding failure of foundations and subsequent collapse of structures or landscaped soil masses.

Tamping rammers are efficient in granular soils with regulated moisture content. Granular soils allow easy movement of the tamping rammer making it suitable for graveling works.

Gravel and Aggregate Compaction

Gravel and aggregates are granular in nature. The vertical jumps created by tamping rammers ensures elimination of air and water molecules from the material structure. The impact to energy conversion ensures particles are closely packed in a process known as dynamic loading.

Dynamic loading occurs when successive impacts from the rammer pad reach the material surface creating stress waves.

Road construction and maintenance are important services to individuals and the general economy of a state. Vehicles have different weight categories; therefore, roads are designed to withstand certain weights based on projected traffic. The base and subbase layers of the road are responsible for handling traffic loads. Materials used in these layers require a high density to sustain design loads.

Compacting the base and subbase layers closely packs the material in a dense structure increasing its load bearing capacity. Settling of material particles in under-layers of roads leads to an un-even surface and potholes formation.

The presence of moisture and air molecules in the base and subbase material results in rutting and cracking in extreme temperature conditions. Tamping rammers eliminate moisture and air particles ensuring longevity of roads.

Tamping rammers have several advantages over other compaction tools. These include;

- Maneuverability- Tamping rammers are small in size and highly maneuverable in tight spaces. This makes them a versatile compaction option for small scale projects and work in enclosed rooms. The design of tamping rammers makes them ideal for compaction of trench bases in civil construction.

- Compaction efficiency- Tamping rammers offer a higher and uniformly distributed compaction force compared to manual compaction tools. Compaction in overlapping thumps ensures no spot is missed out on guaranteeing efficient compaction.

- Project execution time- Tamping rammers make the compaction process easy. They reduce the risk of fatigue on construction personnel allowing them to work for longer hours. As a result, compaction project execution time is significantly reduced.

Compacting Base Materials

Artificial turfs are essential in modern day sports and landscaping aesthetics. Tamping rammers are essential in the initial preparation stages for a durable and functional artificial turf. At the base compaction stage, tamping rammers play a critical role in guaranteeing efficiency.

Efficient compaction creates an even surface over which the turf is laid. Uneven surfaces lead to destruction of the turf due to non-uniform force distribution when a load is applied to it; either by people walking or placing stuff on it.

Drainage is critical for the quality and durability of artificial turfs. Thanks to tamping rammers, efficient compaction ensures proper drainage leaving the turf dry. Waterlogging on artificial turf lowers the quality of the fabric leading to decolorization and tearing away of parts of the turf.

Importance in ensuring durability and stability of pathways and driveways

- Even Surface- Tamping rammers contribute to the creation of an even surface by guaranteeing that the base and subbase material are uniformly crushed. This is crucial for driveways and paths’ visual appeal as well as their practicality because uneven surfaces can be difficult for cars to drive on and uncomfortable for people to walk on.

- Better Distribution of Loads- The compacted base lessens stress on the driveway or pathway and guards against damage from high traffic or vehicle weight by spreading loads more evenly throughout the surface.

- Enhanced drainage- Drainage is essential in safety and usability of pathways and driveways. Efficient compaction by tamping rammers ensures efficient drainage by maintaining a required slope to enhance flow of water and minimize the risk of skidding and sliding.

Conclusion

Tamping rammers have contributed significantly to quality improvement in the construction industry. Their cost effectiveness and versatility make compaction processes cheaper; this improves safety and durability of constructed structures.

There are several tamping rammer brands and designs on the market today. Your choice of a rammer should be guided by your specific project needs and affordability. In road construction, tamping rammers are critical in enhancing load bearing and load distribution aspects of base and subbase layers.

They also play an important role in drainage improvement; ensuring durability in footpaths, driveways, and artificial turfs. For small scale and mid-sized compaction projects, use tamping rammers for high efficiency and timely completion.

Leave A Comment