Soil Compaction Test: Everything You Need to Know

Soil compaction is one of the basic processes in construction and geotechnical engineering. Its fundamental function is to increase soil density by reducing air voids. Proper compaction enhances stability, strength, and load-bearing capacity. That is why it is important for the durability and safety of structures. Ultimately it prevents settlement issues and structural failures.

Compacted soil provides a stable foundation for construction. It improves the structural integrity. Soil compaction prevents long-term damages, i.e. cracks, uneven settling and pavement deterioration. Yet, the efficiency of soil compaction depends upon several factors. These may include soil type, moisture content, and compaction effort applied. The goal of compaction is to achieve optimal performance in the construction projects. So, understanding the compaction test methods is essential.

Contents

Understanding Soil Compaction

What is Soil Compaction

Soil compaction is removing air voids by mechanical densifying the soil. This increases the soil’s density, making it more stable and suitable for construction. The level of compaction affects several soil properties as below:

- Strength

Well-compacted soil has higher shear strength, reducing the risk of structural failure. Stronger soil prevents foundation settling and reduces maintenance and repair costs over time.

- Permeability

Compacted soil has lower permeability, minimizing water infiltration and reducing erosion risks. Permeability is a critical factor for road and embankment construction. Excessive water retention in the soil can weaken the structure of the road.

- Compressibility

Adequate compacted soil experiences minimal settlement over time, ensuring long-term structural stability. Otherwise, soil causes differential settlement which leads to cracking in structures.

Compaction behaviour of Different Types of Soils

There are different types of soils depending on their grain size. Each soil possesses diverse properties and, hence, exhibits variable behaviour under compaction. Leys explore the behaviour of all soils while compacted.

- Cohesive Soils

Clay and silt need optimal moisture levels to achieve maximum compaction. They show plasticity when we apply compaction effort. So the cohesive soils need specific techniques such as kneading and impact compaction.

- Granular Soils

Sand and gravel compact well with a vibratory compactor. The vibration technique is best for granular soils due to their non-cohesive nature. These soils drain water fast. It requires different types of equipment, i.e. vibratory rollers, and plate compactors.

Benefits of Proper Soil Compaction

Proper soil compaction has some general benefits in construction. Let’s discuss it all one by one.

- Structural Failure Prevention

Settlement and heaving are common causes of building and road failures. Compaction reduces the risk of heaving and foundation instability. As it prevents uneven settling, for structures, i.e., bridges, proper compaction is a key player.

- Increased Load-Bearing Capacity

The soil becomes stronger when compacted, without much structural or roadway deformation. High traffic loads are present in both highway and airport runways. The subgrade needs to stay stable and compact to avoid roadway distress.

- Water Infiltration Reduction

A non-absorbent layer pulls water away from the soil. It prevents erosion and frost heave by restricting moisture. It transmits through the substrate, which decreases the soil’s seasonal expansion and contraction. Water infiltration damages the structural stability of compacted soil. It creates subsurface erosion together with sinkholes and leads to collapse.

- Improved Pavement Performance:

Premature cracking occurs in poor subgrades. Proper control of subgrade compaction leads to increased road durability. Subgrade control prevents premature cracking of roads. Adequate ground compaction produces roads that are smooth enough. Roads with compacted bases decrease both vehicle damage and surface degradation. Proper compaction techniques lead to an increase in the duration of pavement service. While the frequency of maintenance work decreases because of compaction techniques.

- Increase in Stability for Retaining Walls and Embankments:

Well-compacted soil prevents lateral movement. The implementation of proper techniques enhances the stability of retaining walls and embankments. Soil that does not reach proper density levels easily triggers slope collapses. It is also prone to landslides, which create dangerous situations.

- Reduced Settlement and Subsidence:

Soil compaction creates foundations which prevent long-term settlement. It minimizes the need for maintenance costs from uneven terrain and road damage. Due to the compacted soil for the foundation, the structure’s alignment remains accurate. Moreover, its designed load distribution remains stable.

Overview of Soil Compaction Tests

Construction field workers need compaction tests to confirm the required density of soil. Testing of materials allows engineering teams to assess the soil. Together with construction contractors, engineers verify soil characteristics for project requirements. During these tests, the personnel uphold safety standards. Project teams benefit from soil compaction tests through their ability. Tests are important to improve construction methods, decrease maintenance and avoid structural damage. Assessment methods exist to check soil compaction by measuring strength and load capabilities.

Purpose of Soil Compaction Testing

Compaction testing verifies how well the soil satisfies engineering standards by the operations. These also verify important data needed for a stable foundation. It also provides satisfactory data for roadbed designs through their verification process.

- The soil has achieved the proper density levels needed for its intended purposes.

- Soil performance in the field depends on the moisture content and compaction results.

- Compliance with construction standards such as ASTM D698 (SPT) and ASTM D1557 (MPT).

- Structures supported by compacted soil will maintain stability throughout their expected operational duration. Engineers use soil compaction tests to ensure stability throughout the operations.

Key Metrics in Soil Compaction Testing

- Maximum Dry Density (MDD)

It is the highest density soil can achieve without moisture interference. Laboratory testing is available to determine the maximum dry density.

- Optimum Water Content (OWC)

It is the moisture level at which soil reaches its MDD, giving the best compaction results. Proper moisture control is critical for uniform compaction across different layers of soil.

- Relative Compaction

Relative Compaction is a percentage that compares field compaction results to laboratory-determined. Usually, 95% or higher relative compaction is acceptable for construction projects.

Methods of Soil Compaction Testing

There are methods to identify the level of compaction and moisture of soil. These methods include both laboratory and field test methods. Now we will elaborate on each of them here.

Laboratory Tests

1. Proctor Test (Standard and Modified)

This test requires a specific testing environment. The Proctor Test evaluates the two key metrics through controlled compaction of samples.

- a) MDD

- b) OWC

Procedure

The procedure involves:

- Test the soil for different levels of moisture content.

- Controlled standard rammer energy compacts the sample inside a moulded container.

- Measuring the resulting dry density.

- The technician will plot a moisture-density graph to quantify OWC and MDD values.

Standard Proctor Test

It engages lower compaction energy at 12,400 ft-lbf/ft³ for load-bearing capacity. It is suitable for sidewalks and landscaping.

Modified Proctor Test

It applies higher compaction energy (56,000 ft-lb/ft³) for heavy construction applications. It is suitable for highways and airport runways.

2. California Bearing Ratio (CBR) Test

Artificial load tests performed by the CBR Test result in soil strength assessments. This field test helps in the strength evaluation of the soil. It is necessary for determining the pavement thickness. During load situations, the soil resistance to deformation increases with its strength level. That’s why CBR testing results increase too.

Procedure:

The test procedure requires the following actions for execution.

- Compact an undisturbed or remoulded specimen in a cylindrical mould at OMC. s.

- Soak the sample for 4 days to assess the soil under wet and simulate field moisture conditions.

- Using a load frame, a metal piston drives into the soil sample at a controlled rate of 1.27 mm per minute.

- Record the required force to penetrate the soil at depths of 2.5 mm and 5.0 mm.

- Compare the recorded force to the standard load values for CBR value as a percentage.

Field Tests

Let’s explore the methods of acquiring the soil compaction level in the field. The following common tests are globally in use.

1. Nuclear Density Test

The nuclear density test is useful for determining the compaction of soil. This method utilizes a nuclear gauge. It emits low levels of radioactive isotopes to measure soil density. For water content, based on radiation scattering and absorption principles.

Procedure:

- It involves placing the gauge on the soil surface or inserting a probe into the ground.

- The device measures the interaction of gamma radiation with soil particles. It allows for precise determination of dry density and moisture levels.

This method provides rapid results and is efficient for large-scale projects. It is ideal for road construction, embankments, and earthworks. Yet, the nature of the equipment is radioactive. It requires specialized training and safety precautions to operate the nuclear gauge. Additionally, strict regulations govern the use, handling, and storage of nuclear testing devices.

2. Sand Cone Test

This method is very accurate but requires careful execution to ensure precise results. Many factors can influence test outcomes. These are environmental conditions, operator expertise, and proper calibration of the sand. The Sand Cone Test validates the compaction in conjunction with other field tests. It also ensures that soil layers meet the required compaction specifications. We can use it in road construction, foundation preparation, and embankment projects.

The sand cone test is a traditional field test that determines soil density. It works by removing a sample and filling the void with calibrated sand.

Procedure:

The procedure includes:

- Dig a hole in the compacted soil.

- Weigh the removed soil sample.

- Fill the hole with known-density sand and measuring the volume.

- Calculate the in-place dry density and comparing it to laboratory compaction values.

3. Dynamic Cone Penetration (DCP) Test

DCP test is especially used in pavement and road construction. It measures the soil resistance by driving a metal cone into the ground with a standard hammer. The penetration depth per blow indicates the soil’s compaction level and strength.

Procedure

The procedure involves:

- Drive a steel cone into the soil using a hammer with a known weight and drop height.

- Measure the penetration depth after each blow to assess soil resistance.

- Record data and calculate penetration rate, then correlate with soil stiffness and compaction.

The DCP test is effective for assessing subgrade conditions and verifying compaction levels. It provides quick and reliable results. That’s why it is preferable for quality control in road construction. Additionally, advanced automated versions improve efficiency with real-time data collection and analysis. Vertek Smart DCP is one of these versions, it reduces human error and ensures precise results. The test is particularly beneficial for evaluating layered soil conditions. It is also good at identifying weak zones in a soil profile.

Factors Influencing Soil Compaction and Test Results

Several factors affect the results obtained from the soil compaction test. These may include:

- Soil Type

- Water Content

- Compaction Effort

Soil Type

Different types of soils do not behave the same under compaction. Alike, the compaction test doesn’t result in the same for all soils. Let’s discuss the soil behaviours below:

- Cohesive Soils: It requires moisture control. So, apply kneading compaction due to their plasticity and ability to retain water.

- Granular Soils: Granular soils need compaction with vibration. Due to loose structure and free-draining properties, it is the most suitable method.

Water Content

- Optimum Water Content (OWC): It ensures the highest compaction efficiency. It is possible by achieving the best balance between lubrication and particle bonding.

- Too Wet: Excess water reduces shear strength. It increases permeability, leading to instability and possible structural failures.

- Too Dry: Insufficient moisture prevents particle bonding. Reducing the density makes the soil more susceptible to compaction failure.

Compaction Effort

The energy applied to compact soil affects its density. Factors include:

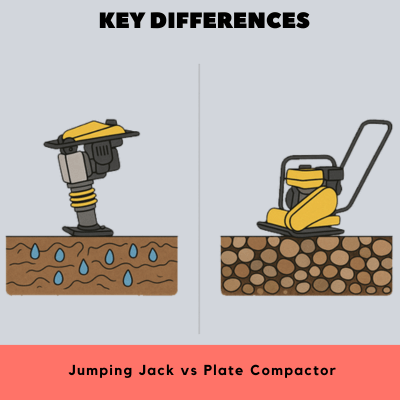

- Type of equipment (static rollers, vibratory rollers, rammers, and plate compactors).

- Number of passes and applied force.

- Soil layer thickness affects how well compaction energy has travelled through the soil.

By understanding these factors, engineers can ensure optimal compaction. They can also improve the stability and longevity of construction projects.

Leave A Comment