Road Roller Compactor:How It Work, Its Shape & Types

Road networks are our primary and most common means of transportation. They exist for thousands of years since the time great Asian and European Empires. They can be even dated back to the times of early native humans.

Ever wonderer how roads are made. The most simple form is a simple clean and moderately flattened path.

Modern road structures are more complex. They are made of several layers starting from subgrade and subbase and going up to the road superstructures.

The lower layers are usually made of a mixture of gravel, sand, clays, and water. While the final finished surface is made with asphalt. The lower layers require a greater degree of compaction while the amount of flattening and smoothness required may be less.

On the other hand, the final asphalt layer is not compacted. Instead, it is only paved and rolled to achieve a flattened and smooth surface. This rolling and paving are done using a road roller compactor.

In this article we will discuss how a roller looks like, how does it work, what is the weight of the common road roller, what are its types, and last we will enlist a few of the top brands manufacturing road rollers.

Contents

The Shape Of a Road Roller

A road roller compactor is a type of mechanical device which has the function of flattening and compression the ground made of several different materials under the action of its weight.

A roller is essentially a dual axle machine. The space between two axles is connected. Usually, power is drawn from the rear-end axle. Two axles are connected by a shaft. The engine can be located either above the rear axle or just behind the front axle. The roller drum is located in the front part of the machine and rotated around the front axle.

On the other hand, the rear axle is fitted with types or two drums- one at each end. If there are tires, usually they are inflatable and made with grooves. They are similar in shape to the tractor tires.

The operator cabin is in between two axles and has all the controls to govern the functioning of the roller. The roller attached to the front can have either the ability to vibrate or not. The drum shape roller attached to the front can also have grooves on its surface.

In this particular case, the roller is used for compacting the lower surfaces of the road.

How Does a Road Roller Work

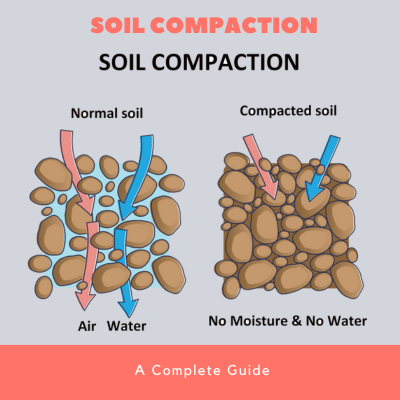

Road rollers use their weight to compress down the surface of the asphalt. The process of compression down can be either static or dynamic.

In static compression, the machine is only rolled over the road surface, while in the case of dynamic compression mechanical means like vibration are used.

As explained earlier, the road roller is made of two or more heavy drums. One of the drums is functioning as the drive while the other functioning as the pushing force. There are some special rollers, in which drum axles move in relative motion concerning each other. This allows them to adjust against the surface irregularities.

Vibratory rollers have drums capable of vibrations. These vibrations are generated due to the weights that are attached to the shaft of a motor. The motor and shaft are located within the roller drum.

Unlike other types of rollers, vibratory rollers possess the ability to fully cover the area underneath the drum wheel. Hence it is more efficient than other types of rollers.

What’s The Weight of a Road Roller

A simple drum roller which is usually a handheld device can weigh up to 45 kg. This type of roller comes with a handle that is pushed or pulled by the worker.

On the other hand, a full-scale roller machine can weigh up to 20 tonnes. A handful of the unit can even weigh up to 60 tonnes.

On the other hand asphalt, the roller can weigh somewhere between 1 to 18 tonnes. Thicker is the layer to be rolled and compacted, heavier would be the piece of equipment used.

Additionally, the density of soil to be compacted also governs the weight of the roller.

Road Roller Compactor Types

Cylindrical Rollers

One of the most basic types of road roller is a walk-behind cylindrical roller. They are lighter in weight and steered by a person in the desired direction. They are normally used for rolling sports grounds and cricket pitches.

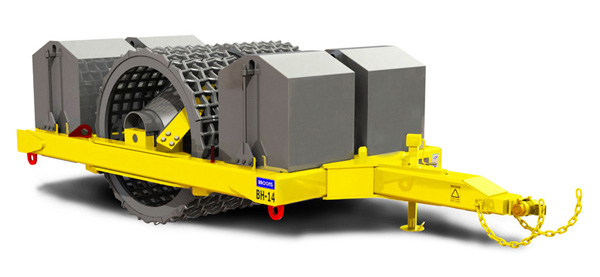

Grid Rollers

Grid rollers as the name suggests are a type of roller that has a network of steel bars. The steel bars form a grid-like pattern on the steel drum. Sometimes, the grid is also ballasted with concrete blocks or rocks or steel attachments for applying more contact pressure. These types of rollers are usually towed or pulled behind a tractor or a truck.

Pneumatic Rollers

Pneumatic rollers are also known as pneumatic tired rollers are a special type of large, ride-on roller having several rows of tires on the front or rear end. The use of rubber tires allows an 80% coverage area and uniform pressure on the surface.

Sheepsfoot

Sheepsfoot rollers sometimes also termed as Padfoot or tamping rollers have many rectangular legs extruding out the drum roller surface. They are ideal for compacting soil and silty clay in road construction work.

Their weight can be extended by adding more ballast in them along with water, damp sand, or mounting steel sections onto it, providing a more efficient compacting job.

Smooth Wheeled And Static Rollers

The tandem or double drum roller is equipped with one steel drum in the front, while the other one is on the back. As the two drums move, this moves the roller.

The efficiency of the tandem roller originates from the two drums — entire sections of a highway can be flattened and paved quickly and effectively.

Vibratory Rollers

Vibratory rollers are almost identical to smooth wheel rollers except for one major difference, which is that they come with a specialized vibrating component. As the roller compacts and flattens the surface, it will vibrate.

Road Roller Compactor Brands

These road roller Compactors are manufactured by several companies including:

- JCB

- Volvo

- CAT

Volvo

Volvo is a Swedish brand most commonly known for cars. It has also a construction equipment manufacturing business. Their most popular models come within the DD and CR series. They have a model weighing up to 59000 lbs.

JCB

JCB is one of the top three manufacturers of construction equipment based in the UK. Their machines weigh between 1700 and 2400 kg. Their most popular models are CT260 and CT160 series.

CAT

CAT in full form caterpillar is an American giant offering range of construction types of machinery. Their most popular models come in the CB series. Their models can weigh up to 30000 lbs.

Conclusions

To conclude, this article discussed several types of road roller compactor and listed their top brands. A full scale roller machine can weigh up to 20 tonenes. Description is also provided on their functioning and shape.

These machines are always twin axle machines. The engine is located in the middle along side the operator’s cabin.

Good information at a glance

glad to hear that it’s helpful

Thankyou

thanks

Minimum Technical Specifications

Operating Weight (kg) 14,000

Working Width (cm) 210-215

Static Linear Load (N/cm) 320-340

Vibration Frequency (Hz) 20-30

Nominal Amplitude (mm) 1.8/0.9

Centrifugal Force (kN) 290/160

Engine DF Cummins or Equivalent

Rated Power (kW/ rpm) 92/2000 or higher

Diameter of Drum(mm) 1515-1535

Static Linear Pressure

300N/cm – 305N/cm

Drum/tire Load

6500/6500kg – 7500/7500kg

Hi GEOFFREY Chilembo, let’s keep in touch by email