Ride-On Trowel: How It Works, How To Use [The Advantages]

Ride-on trowels are indispensable tools in the realm of construction, offering a mechanized approach to achieve smooth and durable concrete surfaces. These powerful machines provide efficiency and consistency in concrete finishing, making them a vital asset for construction professionals.

By understanding the working mechanism, following proper procedures, and prioritizing safety, operators can master the art of using ride-on trowels to achieve professional-grade results.

In this guide, we will explore the step-by-step process, safety considerations, and applications of ride-on trowels, empowering construction professionals to enhance their skills and achieve superior concrete finishes.

Ride-On Trowel

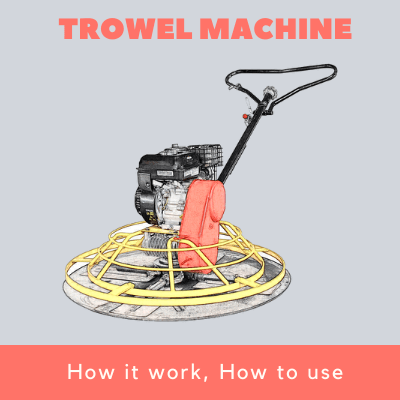

- Ride-on trowels are powerful machines used in the construction industry for concrete finishing.

- Unlike traditional walk-behind trowels, these machines are designed to be operated while riding on top of them, providing enhanced efficiency and productivity.

- Ride-on trowels consist of multiple rotating blades that smooth and level the concrete surface, resulting in a polished and professional finish.

Importance in Construction Projects

- Ride-on trowels play a crucial role in construction projects, particularly in large-scale concrete flatwork applications. They are commonly used for projects such as industrial floors, parking lots, warehouses, and commercial buildings.

- These machines offer several advantages over manual troweling, including faster completion times, improved consistency, and the ability to cover larger areas with ease.

- Additionally, ride-on trowels help achieve higher-quality finishes, ensuring durability and aesthetic appeal in concrete structures.

Contents

Overview of a Ride-on Trowel

Definition and Purpose

- A ride-on trowel is a mechanized equipment used in concrete finishing to achieve a smooth and polished surface.

- Its primary purpose is to replace the manual hand troweling process, offering increased efficiency and productivity in large-scale construction projects.

Key Components

- Engine

- Powers the ride-on trowel and drives the rotation of the trowel blades.

- Typically gasoline or diesel-powered engines, providing the necessary energy to operate the machine.

- Trowel Blades

- Rotating components attached to the underside of the ride-on trowel.

- Made of durable materials such as steel or composite materials to withstand the abrasion caused by contact with the concrete surface.

- The number and configuration of the blades can vary, affecting the troweling pattern and finishing results.

- Steering System

- Enables maneuverability and control of the ride-on trowel.

- Consists of handlebars or a steering wheel that allows the operator to steer the machine accurately.

- Some models may feature intuitive control systems for enhanced maneuverability, such as joystick controls.

- Control Panel

- Houses the operational controls and settings for the ride-on trowel.

- Allows the operator to start and stop the engine, control the blade speed, adjust the pitch of the blades, and manage other operational parameters.

- May include additional features like digital displays for monitoring engine performance and blade rpm.

Working Mechanism

Starting the Ride-On Trowel

- Ensure the ride-on trowel is on a level surface and all safety precautions are followed.

- Turn the ignition key or press the start button to activate the engine.

- Allow the engine to warm up for a few moments before proceeding.

Blade Rotation and Pitch Adjustment

- Engage the blade rotation mechanism, typically done using a lever or switch on the control panel.

- Adjust the pitch of the blades to the desired angle for effective concrete troweling.

- Some ride-on trowels may have adjustable pitch controls that allow fine-tuning of the blade angle while in operation.

Powering the Trowel Forward

- Engage the forward motion control, usually a lever or pedal located on the control panel.

- Gradually increase the speed to move the ride-on trowel forward.

- Maintain a consistent speed to ensure even troweling and avoid creating uneven concrete surfaces.

Steering and Maneuvering the Machine

- Use the handlebars or steering wheel to control the direction of the ride-on trowel.

- Gently turn the handlebars or wheel in the desired direction.

- To maneuver in tight spaces, make gradual and controlled movements, taking care not to damage the concrete or surrounding structures.

Step-by-Step Process

Preparing the Concrete Surface

- Ensuring the Concrete is Properly Leveled

- Before operating the ride-on trowel, ensure that the concrete surface is properly leveled and cured to the desired specifications.

- Use leveling tools such as a bull float or straightedge to check for any high or low spots and make necessary adjustments.

- Removing Excess Debris or Obstacles

- Clear the concrete surface of any debris, rocks, or other obstacles that may interfere with the troweling process.

- Address any large cracks or uneven areas that may require repair or additional attention before troweling.

Operating the Ride-On Trowel

- Starting the Engine

- Follow the manufacturer’s instructions to start the engine of the ride-on trowel.

- Ensure all safety precautions are taken, such as wearing appropriate protective gear and maintaining a clear work area.

- Adjusting Blade Rotation Speed and Pitch

- Set the desired blade rotation speed using the controls on the trowel machine.

- Adjust the pitch of the blades to achieve the desired angle for effective troweling.

- Beginning the Troweling Process

- Position the ride-on trowel at the starting point of the concrete surface to be troweled.

- Lower the trowel blades onto the surface, ensuring they make even contact.

- Moving the Trowel Forward

- Gradually engage the forward motion control to move the ride-on trowel forward.

- Maintain a consistent speed while troweling to achieve even results.

- Steering and Changing Directions

- Use the handlebars or steering wheel to steer the ride-on trowel in the desired direction.

- Make smooth and controlled movements to navigate the trowel without causing damage to the concrete surface.

- Finishing the Concrete Surface

- Continue troweling the concrete surface in overlapping patterns to achieve a smooth and polished finish.

- Monitor the progress and make any necessary adjustments to the blade speed or pitch for optimal results.

Safety Considerations

Personal Protective Equipment (PPE)

- Wear appropriate PPE, including safety goggles or glasses, a hard hat, ear protection, and non-slip footwear.

- Use gloves to protect hands from potential injuries or vibration-related issues.

Safe Operating Procedures

- Read and familiarize yourself with the manufacturer’s operating manual for the ride-on trowel.

- Ensure you are properly trained on the operation of the specific ride-on trowel model.

Preventive Maintenance and Inspections

- Regularly inspect the ride-on trowel for any signs of damage or wear before each use.

- Ensure all mechanical components are in proper working condition, including the engine, blades, and steering system.

Potential Hazards and How to Mitigate Them

- Risk of injury from rotating blades: Keep body parts clear of the rotating blades and never reach underneath the machine while it is in operation.

- Slips and falls: Maintain a clean and dry work area to prevent slips and falls while operating the ride-on trowel.

Advantages and Applications

Advantages of Using a Ride-On Trowel

- Increased Efficiency: Ride-on trowels offer greater productivity compared to manual hand troweling, allowing for faster completion of concrete finishing tasks.

- Consistent Finishing: The mechanized operation of ride-on trowels ensures consistent and uniform troweling results, minimizing the risk of uneven surfaces.

- Time and Labor Savings: By eliminating the need for manual troweling, ride-on trowels reduce labor requirements and enable construction crews to accomplish more within a shorter timeframe.

Common Applications in Construction Projects

- Large Concrete Slabs: Ride-on trowels are commonly used for finishing large concrete slabs such as floors, parking lots, driveways, and airport runways.

- Industrial Warehouses: Ride-on trowels are suitable for achieving high-quality finishes on concrete surfaces in industrial warehouses and distribution centers.

- Commercial Buildings: They are widely used in the construction of commercial buildings, including shopping malls, office complexes, and hospitals, to achieve smooth and polished concrete floors.

Conclusions

In conclusion, a ride-on trowel is a valuable tool in construction projects for achieving smooth and durable concrete surfaces. By following the step-by-step process and understanding its working mechanism, construction professionals can efficiently operate the machine and achieve consistent results.

The significance of a ride-on trowel lies in its ability to cover large areas quickly, saving time and labor while maintaining uniformity. However, it is essential to prioritize safety by adhering to guidelines, wearing proper protective equipment, and conducting regular maintenance. Mastering the art of using a ride-on trowel requires a combination of technical knowledge, experience, and a commitment to safety.

By doing so, professionals can ensure high-quality finishes and a safe working environment.

Sources:

Leave A Comment