Jumping Jack vs Plate Compactor: Which one to Choose

Compaction is the mechanical process of increasing the density of soil. It causes the reorganization of soil particles and the decrease of voids. Highly compacted soils have minimal vacancies, resulting in soil with larger unit weight. Because the soil is weakly connected in its natural form, compaction is required to boost its bearing ability.

Soil compaction is required for all sorts of construction procedures to prevent soil from settling over time. Settling can cause structural damage by creating bending forces and even tilting the structure if compaction is insufficient. Compaction guarantees that the structure or installation is sturdy and free of settling.

A jumping jack compactor uses a series of hits on the ground to level off the uneven surface, increasing the dry density of the soil. On the other hand, plate compactors come in a variety of shapes and attachments, but the main qualities are consistent. When the machine is turned off, the core is a hefty, flat plate that lies on the ground. The plate is moved up and down by either gasoline or diesel motors to compact the soil.

In this article, we will be comparing both jumping jack and plate compactors, which will help to choose the right piece of equipment for the desired job.

Contents

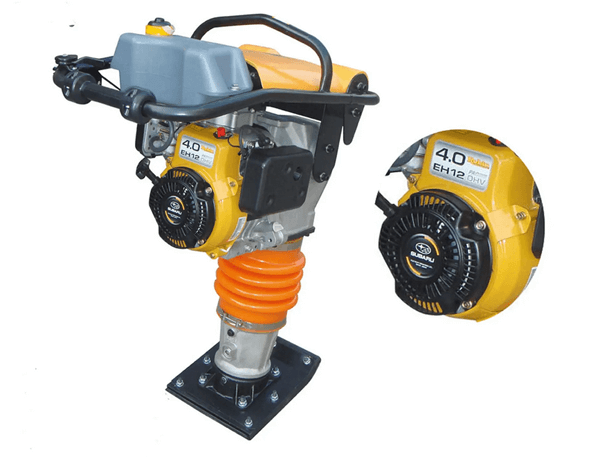

Jumping Jack

A jumping jack compactor, sometimes known as a rammer or a jumping jack tamper, is a machine used to compact earth. It uses a series of hits on the ground to level off the uneven surface, increasing the dry density of the soil. Air and water are removed from the soil during the compaction process.

Jumping Jack Compactors may be used on a variety of soil types, although they are best suited for cohesive soil compaction with a moisture range of 13%. Because of their small size, they are ideal for usage in difficult-to-reach areas such as trenches and ditches. Jumping jack compactors with the most recent design elements can be readily navigated by a single operator.

Main advantage

Jumping jack compactors enable direct compaction to specific areas, making them perfect for confined areas and ditches. Integrating them into smaller projects might result in quicker completion and increased efficiency.

Main disadvantage

On the negative side, they lack force and may not reach the necessary amount of compaction when used on heavy soils or rocks. When dealing with large regions, jumping jacks are likewise less efficient than plate compactors.

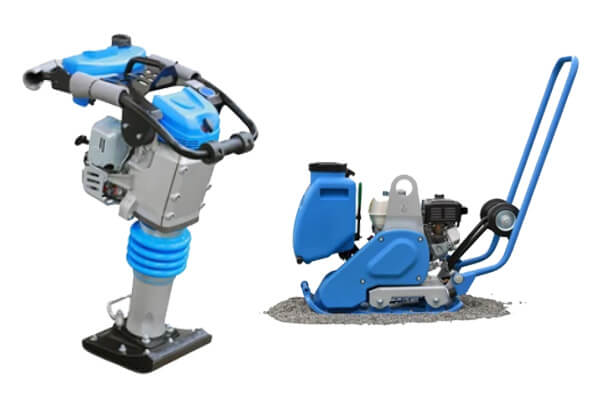

Plate Compactor

While a plate compactor is in operation, the heavy plate on the machine’s bottom rapidly swings up and down. The combination of quick hits, plate weight, and impact compresses or packs the earth beneath more firmly. Plate compactors perform best when used on granular soils, such as those with a high sand or gravel content. In certain circumstances, moistening the soil before utilizing the plate compactor is useful. Two to four passes over the soil should be enough to accomplish optimum compaction, but the compactor manufacturer or rental firm should be able to give some case-by-case recommendations.

Main Advantage

The fundamental benefit of employing a plate compactor is that it improves project durability and performance. These devices compress and tighten the soil, forcing away air spaces. This reduces the possibility of future movement and settling, which can result in fractures, damage, or collapse. It also produces a smoother, more equal surface for gardening and other purposes.

Main Disadvantage

While the weight of the machine is required for effective compaction, it is also one of the vibrating plate compactor’s disadvantages. The machine can be difficult to carry, especially when switched off, and it is normally necessary to transport the equipment to a job site with two persons. When the machine is turned on, the vibrations of the plate move the machine relatively easily; nevertheless, when the plate is still, the machine will not assist the user in moving the majority of it.

Comparison Between Jumping Jack and Plate Compactor

A. Differences in size and weight

A jumping jack compactor is much lighter in size and weight as compared to a plate compactor making it easy to move around.

B. Differences in compaction force

Plate Compactors have a maximum compaction depth of 18 inches, whereas jumping jacks have a depth of 8 inches. Plate compactors can deliver more power and hence deeper penetration up to 18 inches, although jumping jacks may not be able to do so owing to design limits.

C. Differences in maneuverability

Due to being light weigh jumping jack is easy to move around on site. Due to its smaller footprint, it can reach narrow areas. On the other hand, plate compactors offer a higher compaction rate so they are ideal to work on with larger jobs.

D. Differences in cost

Because of their bigger size and higher compaction capabilities, plate compactors are often more expensive than tamping rammers. However, the cost of either type of equipment is determined by the model and its characteristics.

Choosing the Right Compaction Equipment

A. Factors to consider when choosing between jumping jack and plate compactor

- The first consideration when deciding between a vibrating plate compactor and a tamping rammer is the type of soil to be compacted. There are mainly two types of soil: Soil granular and Soil adhesion

- Vibrating plate compactors are most effective with granular soils. Tamping rammers, on the other hand, excel in compacting cohesive soils.

- Furthermore, due to their broader base plates and heavier weight, vibrating plate compactors are suitable for big, flat areas, where they can do the task considerably faster and more efficiently than rammers. Tamping rammers, on the other hand, perform well in deep pits or narrow locations where compactors may struggle to enter.

B. Examples of when to use a jumping jack or plate compactor

It is critical to examine the application area when comparing a Jumping Jack with a Plate Compactor. Jumping Jacks and Plate Compactors may both produce good results when compacting earth, soil, or gravel.

Jumping Jacks are more adaptable than Plate Compactors in general because they may be utilized for aggregate sizes as small as one inch in diameter, allowing for compaction in tight confines and tiny places. This is useful for jobs like trench excavation when the passage is restricted or constrained. Plate Compactors may struggle to fit into these narrow spaces if they fit at all.

A plate compactor, on the other hand, is generally the superior alternative if your project involves dirt or sand that requires thorough compaction. This is because plate compactors employ a reciprocating force that penetrates the soil far deeper than the force of a Jumping Jack, making them ideal for larger operations.

Conclusion

When it comes to compaction, there is frequently no best “one or the other” option for equipment. As a professional contractor, you should invest in BOTH to be well prepared to handle the many sorts of compaction projects/needs you may encounter on your construction sites.

When it comes to soil compaction, both leaping jacks and plate compactors are excellent instruments. Yet, depending on the task at hand, each has distinct benefits and disadvantages that make them more appropriate for specific projects.

Finally, while deciding between the two, considerations such as the type of material being worked on, the amount of the area being covered, and the desired finish will all affect your decision-making process.

Leave A Comment