How to Repair Pavement: Easy DIY & Pro Fixes

Pavement is essential for roads, whether asphalt, concrete or pavers, driveways and walkways. With time, pavements deteriorate due to weather, heavy traffic, or poor drainage. So, timely proper maintenance prevents costly replacements and extends its lifespan also.

Benefits of Appropriate Pavement Repair

Repairing pavements leads to many benefits in daily life. Some of them are here below:

- Safety: Timely pavement repair prevents accidents caused by potholes or uneven surfaces.

- Increased property value: Well-maintained pavement increases its value by improving curb appeal.

- Long-term damage: Pavement cracks are crucial, because they can expand if untreated. Expanded cracks need expensive structural fixes and possible foundation damages.

- Cost-effective maintenance: Regular minor pavement repairs are affordable than resurfacing or replacement.

This detailed guide will explore DIY fixes for pavement damages. Moreover, it explains the professional repair techniques for better road condition. For this, we have discussed step-by-step guidelines for repairing various types of damages.

Contents

What is Pavement Damage

Understanding their construction and types is necessary to understand the damages in pavements. That’s why we will go for the types of pavements first here.

Types of Pavement Surfaces

There are the following types of pavements according to the construction material.

- Asphalt pavement – This type of pavement is flexible and cost-effective. The road surface comprises an asphalt layer. Moreover, most of the driveways are asphalt pavement.

- Concrete pavement – These pavements are famous for their durability. Concrete makes the surface of pavement. That’s why it is suitable for sidewalks, driveways, and parking lots.

- Paver – The pavement comprises brick, stone, or concrete pavers. It gives an aesthetic appeal and offers easy repairability.

Signs That Pavement Needs Repair

Here are some common signs that pavement shows when they require repair and maintenance. These signs are visible and observable easily for example;

- Cracking

In pavements, cracks occur due to various factors. These factors include thermal expansion, water filtration, and natural aging process. There are several types of cracks:

- Hairline Cracks

Hairline cracks are the smallest surface cracks. It appears due to pavement aging, and minor stress.

- Alligator Cracking

This is a network of interconnected cracks resembling reptile skin. It often indicates structural failure in pavements.

- Transverse or Longitudinal Cracks

These cracks run across or along the pavement. It typically appears due to temperature fluctuations and poor construction.

- Edge Cracks

Edge cracks appear near the pavement edges. Inadequate support or drainage issues often result in edge cracks.

- Potholes

In pavements, potholes form when water seeps into cracks, or weakens the subbase. It causes the pavement to break apart. Potholes become larger over time due to freeze-thaw cycles.

- Uneven Surfaces and Depressions

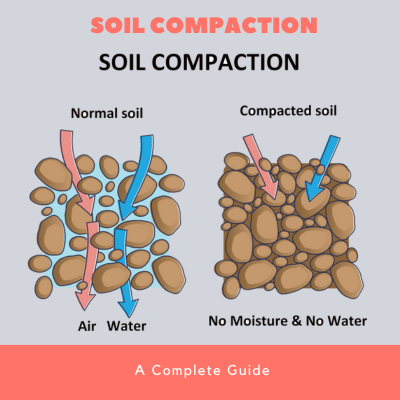

Issues with subgrade or improper compaction produce sunken areas in the pavement. It may lead to water accumulation, and further weakens the pavement surface.

- Surface Erosion and Raveling

Raveling occurs when the pavement surface begins to deteriorate. It causes aggregate in sub-base to loosen and create a rough texture. Surface erosion often occurs due to oxidation, low-quality materials, and poor compaction.

- Spalling

Chipping and breaking of concrete surface is Spalling. Freeze-thaw cycles, reinforcement corrosion or improper finishing techniques produce spalling in pavements.

- Shoving and Rutting

Shoving is the wave-like movement of the asphalt layer of pavement. It may appear on the intersection where vehicles stop and start often. Moreover, Rutting refers to the formation of depressions along wheel paths. This also indicates poor compaction or weak subbase layers.

Types of Pavements and Their Most Occurring Damages

After exploring pavement damages, let’s associate the damages with different types of pavements.

a) Asphalt Pavement: Asphalt pavements are prone to cracking, potholes, and oxidation. It appears over time due to weather exposure and the vehicle weight.

b) Concrete Pavement: Concrete pavements usually develop cracks and spalling (flaking and chipping). It requires proper joint sealing for preventing water infiltration.

c) Pavers: Pavers can lose their stability and become uneven or may shift. It occurs due to uneven ground movement or poor leveling of sub-base material. Uneven require regular re-leveling.

Common Causes of Pavement Damage

Pavement damages due to different factors. Following are the reasons for most of the damages.

- Weather conditions: Weather changes, freeze and thaw cycles lead to cracking and potholes. while extreme heat softens asphalt, making it susceptible to ruts and depressions.

- Heavy traffic loads: Heavy traffic loads produce wear and tear, weaken the structure.

- Poor drainage: Water retention leads to seepage in pavement layers. It causes erosion, weakening and cracking due to thawing.

- Subsurface movement: Soil layer movement or shift in soil composition leads to heave and sink in pavements.

- Age of pavement: With pavement ages, the binding materials deteriorate. It makes the pavement more vulnerable to damage.

Tools and Materials Needed for Pavement Repair

Several tools are available for repairing pavements. Each tool is specific for a certain type of repair. Let’s elaborate on the tools and materials conforming to the pavement repair. Some of them are basic tools, however, others are options. that may or may not require.

Basic Tools

Basic tools for pavement repair works are as below:

- a) Crack filler and sealant: Crack filler is available to fill the minor cracks. However, sealant is also useful for preventing further water infiltration.

- b) Asphalt patching compound: The asphalt patching compound is essential for repairing potholes. It is also helpful to repair large cracks.

- c) Paving saw: It is a cutter which is suitable to cut out damaged pavement sections. Usually it is used before applying new material to the deteriorated surface.

- d) Tamping machine: Tamping machine is a type of compactor. It helps in compaction of patching material for a solid, long-lasting repair.

- e) Shovel and broom: It is necessary for cleaning debris and spreading patching material.

- f) Pressure washer: The pressure washer removes dirt. and loose material. Usually, it is used before filling sealant or crack filler.

Optional Equipment for Large-Scale Repairs

We will now enlist the optional equipment that is required for large-scale repairs. Such as;

Infrared asphalt heaters heat asphalt to make it soft. It becomes suitable for performing seamless repair activities.

Industrial seal coating sprayer ensures even application of seal coat for large areas.

Hot mix asphalt machine functions to manufacture lasting high-quality areas for material patching.

Step-by-Step Guide to Repairing Different Types of Pavement Damage

We have discussed the pavement, reasons of damage, and the remedial tool equipment. In this section, we will guide you step-by-step to repair the pavement.

Crack Repair

Hairline Cracks

As this type of crack may appear in both asphalt and concrete pavement, it can be generally repaired as:

- Firstly, use a wire brush or pressure washer to remove dust and debris.

- Fill the crack using a rubberized asphalt or concrete filler, applied with a caulking gun.

- After filling the crack, use a putty knife to level the filler and allow it to dry completely.

- Lastly, a seal coat should be applied over the repaired section to prevent further damage.

Alligator Cracking

These are bigger cracks than the hairline one. So, repairing them includes the following steps:

- For alligator cracks, we need to replace the damaged section. So, use a paving saw to remove the affected section. Clear away the damaged asphalt or concrete.

- Use a hot mix or cold patch compound for a new pavement layer, then compact with a tamper.

- Apply a final sealant to protect against moisture penetration.

Fixing Potholes in Pavement

Potholes require repair through filling the deteriorated surface. Following are the steps to repair such damaged pavement.

- Firstly, cleaning the pothole is essential so remove loose debris and standing water.

- After cleaning, apply a bonding agent. It will help new material adhere to the existing pavement.

- To fill the hole, use hot-mix asphalt for a long-lasting repair or a cold patch for temporary fixes.

- Use a tamper or roller to ensure a smooth finish and compact the filled material properly.

- After compaction, seal the repair with suitable sealant. It prevents moisture from entering and causing further damage.

Repairing Depressions and Uneven Surfaces

Depressions and uneven surfaces can appear in any kind of pavement. To address them, we can follow these steps.

- First, you should determine the cause of the pavement’s depression. Investigate poor foundation, water damage, or settling issues.

- To remove the damaged section, excavate the base layer if necessary.

- To restore, fill the depression with a stable material and compact it afterwards.

- Apply fresh pavement by using asphalt or concrete to match the surrounding surface.

Fixing Raveling and Surface Erosion

You can fix travelling and surface erosion by following the steps below:

- Clean the affected area: Remove loose aggregate with a broom or pressure washer.

- Apply a slurry seal or micro-surfacing treatment on the affected area. It provides a new surface layer and protects against further wear.

- Apply a seal coat as it helps maintain surface integrity and extend pavement life.

Fixing Drainage Problems in Pavement

- Identify problem areas: Look for water pooling or low spots.

- Install proper slopes or drainage channels: Redirect water away from the pavement.

- Use permeable paving solutions: This helps improve water absorption and reduces erosion.

Preventive Maintenance to Extend Pavement Lifespan

Time-to-time, repairing pavements can lead to a long lifespan. But we can achieve a long life of pavements by adopting some preventive steps such as;

- Regular inspections: One should check at least once a year to catch early signs of damage.

- Crack sealing: Upon observing cracks, fill cracks every 2–3 years to prevent water infiltration.

- Sealcoating: Apply every 3–5 years to protect against UV damage and wear.

- Drainage management: Ensure proper slope and drainage system to prevent standing water.

- Limit heavy loads: Reduce pressure on weak pavement areas to prevent structural failure.

- Use high-quality materials: Invest in durable sealants and patching compounds for long-term effectiveness.

DIY vs. Professional Pavement Repair: When to Call a Pro

Now, we will differentiate and elaborate on the DIY and professional repair. Although we will discuss that when the professional assistance is essential.

DIY Repairs

The term “DIY repairs” is common for the repair works of small pavement damages such as

- Small cracks and minor potholes.

- Surface sealing to protect against oxidation and moisture.

Professional Repairs

Professional repairs are carried out for big damages as below:

- Large cracks wider than ¼ inch.

- Full-depth patching and resurfacing projects.

- Drainage-related issues that require excavation.

Cost Comparison

The total cost of DIY projects remains lower than those of professional repairs. Professional pavements repair services come at a high cost because:

The cost covers skilled labor services alongside a guaranteed project completion.

A professional worker completes the task significantly and more quickly.

Inaccurate pavement repairs made by unqualified individuals will need additional work. It will lead to more expensive long-term expenses.

Many professionals offer warranties for their work, providing peace of mind.

- DIY: Materials cost between $50–$300 depending on the repair.

- Professional: Costs range from $2–$10 per square foot.

Choosing the Best Paving Contractor

There are some to-dos before hiring a pavement repair contractor such as:

- Verify licensing and insurance.

- Check reviews and ratings.

- Request multiple quotes for cost comparison.

- Ensure a written estimate and warranty.

Frequently Asked Questions (FAQs)

How Often Should Pavement Be Resealed?

Reseal asphalt every 3–5 years; concrete can last longer but benefits from periodic sealing.

What Is the Best Time to Repair Pavement?

Spring and summer provide optimal temperatures for asphalt and sealants to cure.

Can I Repair Pavement in Winter?

Cold patching works in winter, but hot mix asphalt repairs are best in warm conditions.

Leave A Comment