The Ultimate Guide to Tamping Rammer Types,Brands,Parts,Use

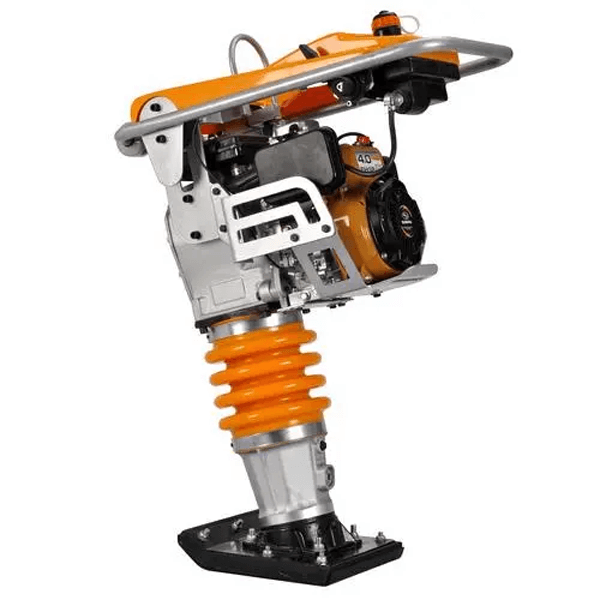

Tamping rammers are equipment used for compacting soil by tapping and are especially useful in tight locations where other machines cannot be utilized. It is used to compress earth around foundations, prepare the soil for concrete pouring, compact soil used to fill ditches for pipelines or cables, and compact asphalt in the road or pavement repair work.

Rammers have a strong impact force (because of the high amplitude of the sole displacement) and are thus ideal for compacting cohesive or semi-cohesive soils. Tamping rammers employ three different forms of compactions: impact, vibration, and kneading.

In this article, we will explore the different types and brands of tamping rammer. We will discuss some of the major parts of a rammer and the applications of tamping rammers.

Contents

Different Types of Tamping Rammer

Electric Tamping Rammer

Instead of a gasoline engine, an electric rammer features an electric motor. One of the major advantages of an electric rammer over a gasoline rammer is that it is quieter and lighter usually.

However, it might have less power as compared to modern gasoline-powered tamping rammer. Moreover, one major issue with them is that there is a cord. So you need a constant electricity connection to operate them and your movement of the rammer is also limited by the length of the cord.

Gasoline Tamping Rammer

Robin engine

Rammers for tamping are ergonomically designed and well-balanced. Tamping rammers are adaptable, portable, and visually appealing. They run on the trusty Robin engine for maximum comfort and efficiency. The robin engine is sturdy and equipped with a few great features: Without the need for several specialized/expensive tools/jigs, a cast-iron cylinder liner with a chain-driven camshaft and oil fill/dipsticks on both sides may be fixed.

Honda engine

Four-cycle gasoline engines are used to power the majority of rammers on the market today. Several rammer makers employ specially designed Honda GX100 four-cycle engines because they are reliable, run on regular gasoline, and emit little pollution. In contrast to older rammer engines, which were restricted to a 20-degree working angle, the Honda GX engines enable the rammer to operate at acute angles.

Battery Tamping Rammer

Emission-free, cordless, battery-powered rammers are perfect for trenches and other poorly ventilated spaces. They are simple to use and start with the push of a button. These rammers give the same output as their gasoline-powered predecessors without compromising performance thanks to the strong battery.

Major Brands of Tamping Rammer

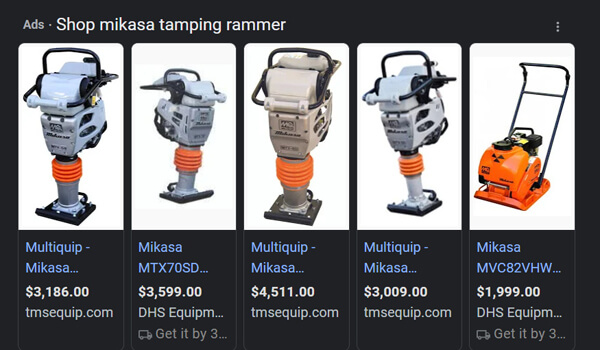

Mikasa

The three tamping rammer series offered by Mikasa are the MTX, MT, and Trench rammer. Honda gasoline or diesel engines power each and every model. There are 30 to 40% fewer vibrations thanks to the specifically built vibration system. They usually have 2L engines and can produce an impact force of 1000 kg with 700 impacts per min.

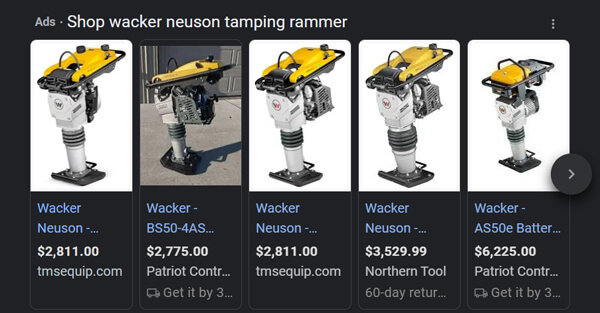

Wacker Neuson

Wacker Neuson offers three distinct tamping rammer models: two-stroke, four-stroke, and battery-powered.

The AS50e and AS60e cordless, battery-powered rammers are best for use indoors during building and remodeling projects, as well as in trenches and other noisy environments like hospitals.

The two- and four-stroke rammers from Wacker Neuson are known for their high performance and durability. The lengthy shoe stroke and high percussion rate produce excellent compaction results due to its quick advanced travel, high energy stroke, and percussion rate.

They can produce an impact force of 4000 lbs with 680 impacts per min.

Parts of Tamping Rammer

Following are some of the major parts of a tamping rammer

Parts for Engine

- Oil Cylinder

- Driving engine

- Frame

- Drive handle

- Fuel tank

Parts for rammer

- Bellows

- Gear reducer

- Anti-vibration rubber elements

- Compacting plate

Uses of Tamping Rammer

Compacting Soil

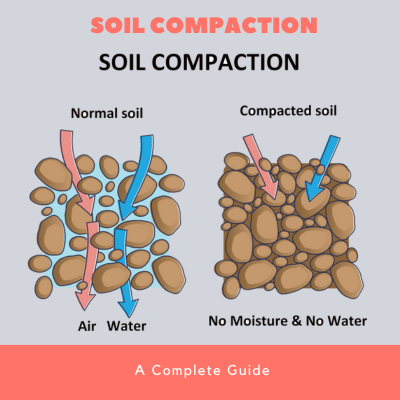

Because each type of soil responds to its constituent components differently, various compaction techniques are needed for each type of soil. t is important to match the soil type with the appropriate compaction procedures in order to obtain the necessary amount of compaction. Cohesive soils, or soils composed of particles that stay together, such as clay, need a tamping rammer that delivers a direct blow with a strong impact force. In order to create a firm, stable ground surface to work with, the soil particles must be properly pushed, pushing any air or water trapped between them to escape. Yet, a vibrating plate is frequently a more efficient kind of compaction if you are working with granular materials, such as sand.

Pavement Compaction

Tamping rammers are perfect for compacting asphalt in projects like paving parking lots and repairing roads. The factors involved in road design will determine the tamping rammers to use. A thicker asphalt layer is necessary for roads and pavements with high traffic, which suggests that a larger tamping rammer should be utilized. One of the greatest rammers to utilize for compacting asphalt is the MT-77HRL.

Compacting Gravel

Gravel compaction can be done in order to prepare the base for roads, bridges, and other constructions using a tamping rammer.

Surface Finishing For Concrete

Tamping rammers can be used to polish and level concrete surfaces for things like patios, sidewalks, and flooring. Light rammers with a higher frequency but less compaction power are ideal for fine finishing.

Renting vs Buying Tamping Rammer

Advantages of Renting Tamping Rammer

It pays to have a go-to source for all the gear, tools, and machines you need whether you have a short-term project or you need to replace a malfunctioning tamping rammer quickly. Renting a tamping rammer is an affordable method to get the models you need if you’re looking for a temporary solution that can conduct high-performance compaction with excellent speed and agility.

Advantages of Buying Tamping Rammer

Owning a tamping rammer allows you to do tasks more quickly, which lowers your labor costs. The profit margin for work increases as your labor cost falls. Being able to exceed your clients’ expectations will result in a drop in labor costs as well as a trend. However, please do the math before buying it. If you have only one short term job to do. It might not be a good idea to own a rammer.

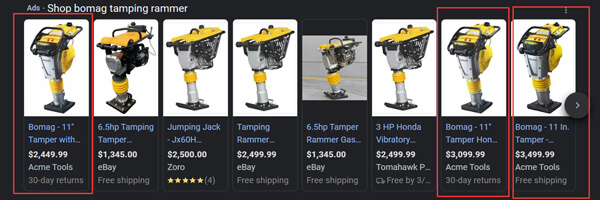

Price of Tamping Rammer

Average Cost of Tamping Rammer

Tamping rammers can cost on average around 500 USDs. Usually, battery powered tamping rammers are the expensive ones

Conclusion

Tamping rammers are tools for tapping earth into place, and they are particularly helpful in confined spaces where other devices cannot be employed. An electric rammer has an electric motor rather than a gasoline engine. Electric rammers often operate more quietly and are lighter than gasoline rammers, which is one of their main advantages.

Although there are many characteristics to take into account that improve performance, ergonomics, maintenance, and more, the engine is still the major way that rammer manufacturers may be distinguished from one another.

Leave A Comment