The Ultimate Guide to Rebar Spiral Bending Machine

If you’re involved in construction or manufacturing, you’re likely familiar with rebar- a reinforcement bar used to provide strength and stability to concrete structures.

But have you heard of a rebar spiral bending machine? Here, we’ll take a deep dive into what a rebar spiral bending machine is, its importance, benefits, working principle, types, applications, and its maintenance and safety.

Contents

Introduction

A rebar spiral bending machine is a specialized piece of equipment designed to bend rebar into a spiral shape. This machine is often used in the construction industry to create reinforcement for concrete structures such as columns, beams, and other architectural features. Let’s consider some of its perks and benefits.

Importance and Benefits

Using a rebar spiral bending machine provides several important benefits, including:

- Improved productivity

- Precision and accuracy

- Consistency

- Reduced waste

If you’re involved in construction or manufacturing and haven’t considered using a rebar spiral bending machine, now is the time to explore its many advantages.

Working Principle

To fully optimize the benefits and perks of a rebar spiral bending machine, it is crucial to understand its working principle. Understanding this principle would ensure its proper usage and maintenance. Highlighted below are the various components of a rebar spiral bending machine and how they work together to create a spiral bend.

- Bending Disk

- Mandrel

- Drive System

- Control Panel

How each component works

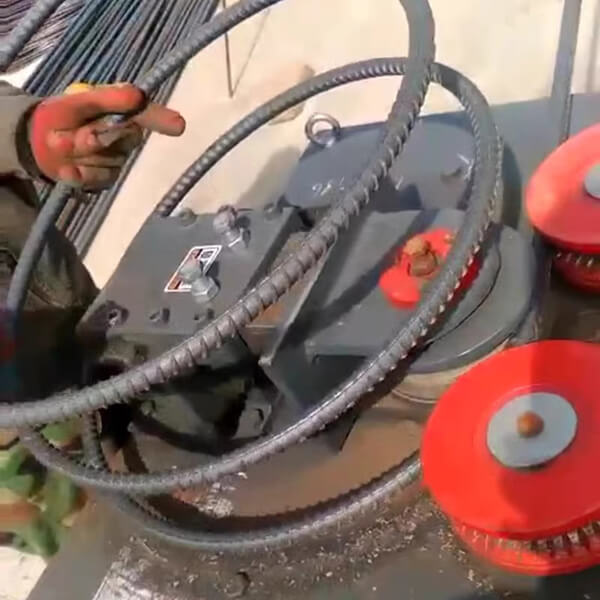

The working principle of a rebar spiral bending machine is simple. The rebar is placed in the mandrel, and the drive system is activated to rotate the mandrel. As the mandrel rotates, the bending disk shapes the rebar into a spiral shape. The control panel allows the operator to control the speed and direction of the mandrel and bending disk.

To create a spiral bend, the operator needs to adjust the position of the bending disk and mandrel. The angle and radius of the spiral bend are determined by the distance between the bending disk and mandrel. The operator can adjust this distance to create different spiral bends.

The rebar spiral bending machine is versatile and can be used to create spiral bends of different angles and radii. The machine is designed to handle different rebar diameters and can create spiral bends of up to 180 degrees.

Types of Rebar Spiral Bending Machines

Rebar spiral bending machines come in different types, each with unique features, advantages, and limitations. Let’s take a closer look at the different types of rebar spiral bending machines available in the market.

Manual Rebar Spiral Bending Machine

Manual rebar spiral bending machines are the simplest type of rebar bending machines available in the market. They are operated by hand, and their bending capacity is limited. These machines are ideal for small-scale projects that do not require a high volume of bending.

Advantages:

- Easy to operate

- Affordable

- Lightweight and portable

- Suitable for small-scale projects

Limitations:

- Limited bending capacity

- Slow bending speed

- Requires physical effort

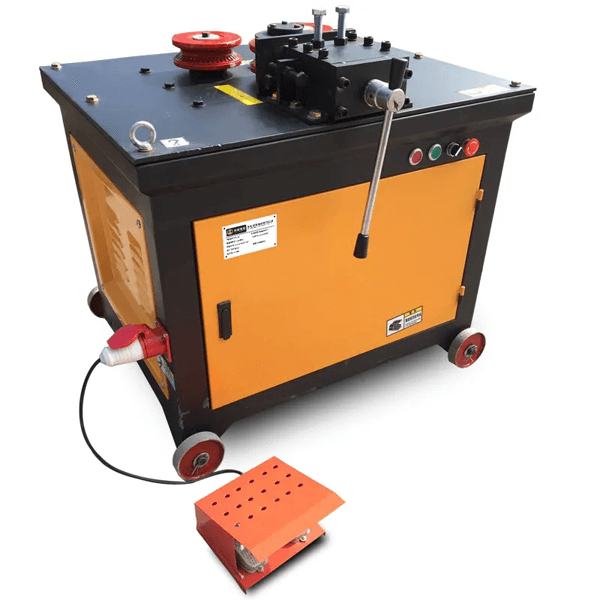

Hydraulic Rebar Spiral Bending Machine

Hydraulic rebar spiral bending machines are the most advanced type of rebar bending machine available in the market. These machines are powered by hydraulic pressure, which enables them to bend rebar with high accuracy and precision. They are ideal for large-scale construction projects that require a high volume of bending.

Advantages:

- High bending capacity

- Fast bending speed

- Accurate and precise bending

- High level of automation

- Low maintenance requirements

Limitations:

- Higher cost than manual machines

- Requires a power source and hydraulic fluid

- Less portable than manual machines

Where to Use

Rebar spiral bending machines have revolutionized the construction industry by providing a cost-effective and efficient method for bending reinforcing steel bars. These machines have a wide range of applications in various fields, including construction, engineering, and manufacturing. Some of the various fields where Rebar spiral bending machines are used include:

- Construction Industry: These machines are used to produce various types of curved and spiral-shaped rebar structures that are used in the construction of buildings, bridges, tunnels, and other structures. One example of the use of rebar spiral bending machines in construction is the construction of the Burj Khalifa in Dubai, which is currently the tallest building in the world.

- Engineering Projects: Rebar spiral bending machines are used extensively in engineering projects that require the use of curved or spiral-shaped rebar structures. For example, these machines are used in the construction of water treatment plants, power stations, and other industrial facilities.

- Manufacturing Industry: Rebar spiral bending machines are also used in the manufacturing industry to produce a wide range of metal products. These machines can be used to bend and shape various types of metal, including steel, copper, and aluminum.

Factors to Consider When Choosing

If you’re looking to invest in a rebar spiral bending machine, there are a few key factors you should consider to ensure that you choose the right machine for your needs.

Key Considerations when Selecting a Rebar Spiral Bending Machine:

- The capacity of the machine must be capable of handling the size and weight of the rebar you’ll be using.

- Speed: A faster machine will be more efficient and can help you to complete projects in a timely manner.

- Accuracy: Look for machines that have high accuracy ratings to ensure that your spirals are of the highest quality.

- Durability: Purchase machines that are made of high-quality materials and have a robust construction to ensure that they can withstand heavy use.

- Ease of Use

When comparing different rebar spiral bending machines, there are several factors that can affect their efficiency and productivity. Some of these factors include:

- Power

- Automation

- Versatility

- Maintenance

By considering these factors, you can choose the right rebar spiral bending machine for your needs, which can help you to complete projects quickly and efficiently while maintaining high quality.

Maintenance and Safety

To ensure optimal performance and longevity, it is crucial to maintain and operate rebar spiral machines correctly. Some of the perks of proper maintenance include the following:

- To ensure the proper functioning of the machine.

- Helps identify potential issues early on and prevent them from escalating into more significant problems.

- Helps to extend the machine’s lifespan and minimize downtime due to breakdowns or repairs.

In addition to regular maintenance, it is also essential to follow the necessary safety procedures when operating the machine. The following are steps for maintaining a rebar spiral bending machine to ensure optimal performance and longevity:

- Lubricate all moving parts regularly, as specified by the manufacturer. Use the recommended lubricants.

- Keep the machine clean and free from debris, dust, and other foreign materials.

- Regularly inspect the machine for any signs of wear and tear or damage.

- Calibrate the machine regularly to ensure it is bending the rebar accurately to the required specifications.

- Store the machine in a dry and secure location when not in use.

Conclusion

In summary, rebar spiral bending machines play a critical role in the construction and engineering industry. These machines provide a reliable and efficient method of bending rebar spirals, which is a crucial aspect of constructing reinforced concrete structures.

By investing in a high-quality rebar spiral bending machine and following the safety precautions and maintenance tips provided in this guide, you can ensure that your construction projects are completed on time and to the highest quality and safety standards.

Leave A Comment