5 Best Rebar Benders for Construction Professionals

Rebar, short for reinforcing bar, is a steel bar used as a tension device in reinforced concrete and masonry structures. It is typically made of carbon steel and has ridges or deformations on its surface to improve the bond between the steel and concrete. Rebar is essential in construction because it helps to increase the strength and durability of concrete structures.

When concrete is poured around rebar, the two materials work together to resist various types of forces. Concrete is strong in compression but weak in tension, whereas steel is strong in both tension and compression. By placing rebar within the concrete, the steel can resist the tensile stresses that the concrete would otherwise be unable to withstand. This results in a stronger and more durable structure that is better able to resist external forces, such as wind, earthquakes, and heavy loads.

Rebar benders are tools used to bend and shape rebar to the desired angles and dimensions, making it easier to install rebar within a structure and ensuring that it conforms to the required specifications.

Contents

Factors to Consider When Choosing the Best Rebar Bender

- Size and type of rebar to be bent: Consider the diameter and type of rebar that the bender can handle, as some benders may only be suitable for specific sizes or types of rebar.

- Type of bender: Decide whether you need a manual or electric rebar bender, depending on your budget and the volume of rebar that you need to bend.

- Capacity and bending angle range: Look for a bender with a suitable capacity and bending angle range to meet your project’s specific requirements.

- Durability and ease of use: Choose a rebar bender made from high-quality materials that can withstand frequent use and harsh job site conditions. Also, look for a bender that is easy to operate and maintain.

- Portability and storage: Consider the weight and size of the bender, as well as its portability and storage options, especially if you need to move it frequently between job sites.

- Cost and value for money: Evaluate the cost of the bender relative to its features and capabilities, and consider whether it represents good value for money compared to other options on the market.

- Brand reputation and customer reviews: Research the brand reputation of the manufacturer and read customer reviews to get an idea of the bender’s performance and reliability in real-world conditions.

Top 5 Best Rebar Benders on the Market

BN Products MBC-16B Rebar Bender

This electric rebar bender can handle up to 5/8″ diameter rebar and has a bending angle range of 0-180 degrees. It features a foot pedal switch for hands-free operation and is made from durable materials for long-lasting performance.

Kaka Industrial UB-100A Heavy-Duty Universal Bender

This manual rebar bender can bend various types of metal, including rebar, up to 2″ wide and 1/4″ thick. It features an adjustable stopper for repeatable bending and a long handle for increased leverage.

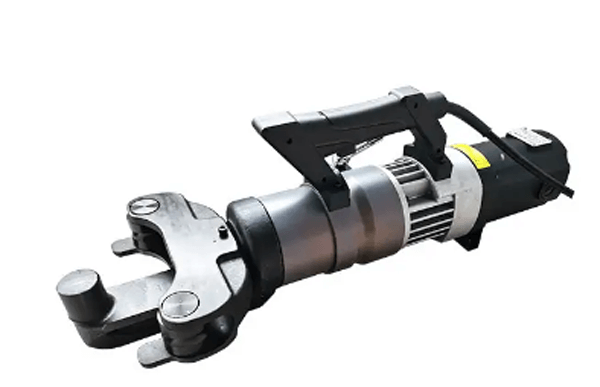

Happybuy Electric Hydraulic Rebar Bender

This electric rebar bender can handle up to 5/8″ diameter rebar and has a bending angle range of 0-130 degrees. It features a foot pedal switch for hands-free operation and a hydraulic system for efficient bending.

CCTI Electric Rebar Bender

This electric rebar bender can handle up to 5/8″ diameter rebar and has a bending angle range of 0-180 degrees. It features a foot pedal switch for hands-free operation and a powerful motor for efficient bending.

Metabo HPT VB16Y Portable Rebar Bender and Cutter

This manual rebar bender and cutter can handle up to 5/8″ diameter rebar and has a bending angle range of 0-180 degrees. It features a compact and portable design for easy transportation and storage, as well as a double-insulated motor for increased safety.

Comparison of the Top 5 Best Rebar Benders

| Product | Capacity | Bending Angle Range | Type | Pros | Cons |

| BN Products MBC-16B Rebar Bender | 5/8″ | 0-180 degrees | Electric | Hands-free operation, durable construction, easy to use | Higher price point, limited bending range |

| Kaka Industrial UB-100A Heavy-Duty Universal Bender | 2″ wide, 1/4″ thick | N/A | Manual | Can bend various types of metal, adjustable stopper, portable | Requires physical effort, not for heavy-duty use |

| Happybuy Electric Hydraulic Rebar Bender | 5/8″ | 0-130 degrees | Electric | Hands-free operation, hydraulic system, efficient bending | Limited bending range, hydraulic fluid leaks |

| CCTI Electric Rebar Bender | 5/8″ | 0-180 degrees | Electric | Powerful motor, hands-free operation, efficient bending | Higher price point, limited bending range |

| Metabo HPT VB16Y Portable Rebar Bender and Cutter | 5/8″ | 0-180 degrees | Manual | Compact and portable, double-insulated motor, easy to use | Requires physical effort, limited capacity |

Pros and Cons

BN Products MBC-16B Rebar Bender:

Pros: Hands-free operation, durable construction, easy to use

Cons: Higher price point, limited bending range

Kaka Industrial UB-100A Heavy-Duty Universal Bender:

Pros: Can bend various types of metal, adjustable stopper, portable

Cons: Requires physical effort, not for heavy-duty use

Happybuy Electric Hydraulic Rebar Bender:

Pros: Hands-free operation, hydraulic system, efficient bending

Cons: Limited bending range, hydraulic fluid leaks

CCTI Electric Rebar Bender:

Pros: Powerful motor, hands-free operation, efficient bending

Cons: Higher price point, limited bending range

Metabo HPT VB16Y Portable Rebar Bender and Cutter:

Pros: Compact and portable, double-insulated motor, easy to use

Cons: Requires physical effort, limited capacity

What customer say

On Amazon, Happybuy Electric Hydraulic Rebar Bender has the most positive reviews. One customer said: “This is a great machine for the money. It is a bit heavy to work with but bent my rebar for my new home – no problem. even able to bend two at a time for smaller 1/2inch piece. Great Buy”

Conclusions

Choosing the best rebar bender is important to ensure efficient and accurate bending of rebar, and based on the comparison, the BN Products MBC-16B Rebar Bender is recommended for its hands-free operation, durability, and ease of use; final considerations include considering the specific needs and requirements for the project, as well as the capacity, type, and portability of the bender.

Leave A Comment