How to Balance Trowel Machine Like a Pro: Step by Step

Trowel machines, also known as power trowels, are essential tools in creating smooth and level concrete surfaces. Achieving the proper balance of these machines is vital for ensuring optimal performance, safety, and high-quality finishes.

In this article, we will explore the significance of balancing a trowel machine, understand its components, discuss the effects of imbalance, and outline the steps involved in achieving and maintaining balance.

By delving into this topic, we can enhance our understanding of the critical role balance plays in civil engineering and its impact on construction projects.

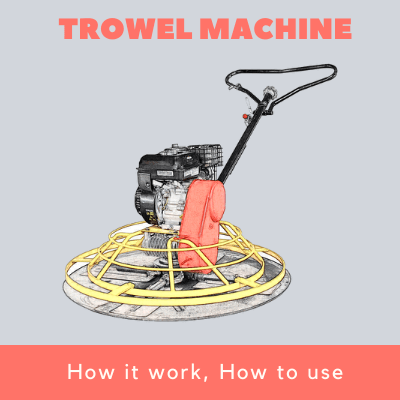

Brief explanation of a trowel machine:

- A trowel machine, also known as a power trowel or a concrete helicopter, is a construction equipment used to create a smooth and level surface on freshly poured concrete.

- It consists of one or multiple rotating blades, often referred to as trowels or pans, which are powered by an engine.

Importance of balancing a trowel machine:

- Balancing a trowel machine is crucial for its optimal performance and safety.

- Properly balanced trowel machines ensure even distribution of weight on the blades, which results in a smooth and consistent finish on the concrete surface.

- Imbalanced machines can cause uneven or wavy concrete finishes, leading to potential safety hazards and the need for additional repairs.

Purpose of the post:

- It aims to highlight the importance of maintaining a balanced trowel machine for achieving high-quality concrete finishes and ensuring the safety of construction workers.

- The post will discuss the potential issues arising from an imbalanced trowel machine and provide insights on how to properly balance the equipment for optimal performance.

Contents

Understanding Trowel Machine Balance

Components of a trowel machine

- A trowel machine consists of several key components that contribute to its operation and balance.

- The main components include the engine or motor, handlebars for maneuverability, rotating blades or pans, and a gearbox or transmission system.

- These components work together to provide power, control, and the necessary rotation for the blades to smooth the concrete surface.

Importance of proper balance

- Proper balance is crucial for a trowel machine’s efficient and effective operation.

- Balanced trowel machines ensure that the weight is evenly distributed on the blades, preventing uneven finishes on the concrete surface.

- The balance of the machine also affects the operator’s control and maneuverability, allowing for smoother and more precise operation.

Effects of an imbalanced trowel machine

- An imbalanced trowel machine can lead to various negative effects, both on the quality of the concrete finish and the overall operation:

- Uneven finishes: Imbalance causes uneven weight distribution on the blades, resulting in inconsistencies in the smoothness and levelness of the concrete surface.

- Increased operator fatigue: Imbalance puts additional strain on the operator, leading to increased fatigue during operation and potentially affecting their control and precision.

Preparing for Balancing

Ensure the trowel machine is turned off

- Before attempting to balance a trowel machine, it is crucial to ensure that the machine is completely turned off and disconnected from any power source.

- This precautionary measure ensures the safety of the operator during the balancing process and prevents any accidental activation of the machine.

Inspect the trowel machine

- Conduct a thorough visual inspection of the trowel machine to identify any visible damage or loose components.

- Check for cracks, bends, or any signs of wear and tear that may affect the machine’s balance or performance.

- Tighten any loose parts, such as bolts, nuts, or fasteners, to ensure the machine is structurally sound before proceeding with the balancing process.

Clean the machine

- Clean the trowel machine to remove any dirt, dust, or debris that may have accumulated on its surfaces, especially around the blades and rotating components.

- Use a brush, compressed air, or a damp cloth to remove any foreign particles that can interfere with the machine’s balance or impede its movement.

- Ensuring a clean machine helps maintain proper weight distribution and allows for accurate balancing.

Balancing Process

Adjusting the pitch angle

Explanation of pitch angle:

- The pitch angle refers to the angle at which the blades of the trowel machine are set in relation to the concrete surface. It plays a crucial role in determining the machine’s balance and its ability to create a smooth and level finish.

Determining the correct pitch angle for the trowel machine:

- The correct pitch angle depends on various factors, including the desired finish, and the machine’s specifications. Consult the manufacturer’s guidelines or specifications to determine the recommended pitch angle range for your specific trowel machine.

Adjusting the pitch angle using the pitch control mechanism:

- Most trowel machines are equipped with a pitch control mechanism that allows for adjusting the angle of the blades. To increase the pitch angle, adjust the pitch control mechanism to raise the leading edge of the blades. To decrease the pitch angle, adjust the mechanism to lower the leading edge of the blades.

Balancing the blades

Checking the blade wear:

- Inspect the blades of the trowel machine for any signs of wear, such as uneven edges or excessive thinning.

- Worn-out blades can cause imbalance and affect the quality of the concrete finish. Replace any worn or damaged blades with new ones to ensure proper balance.

Balancing the blades using a blade balancer or similar tool:

- Utilize a blade balancer or a similar tool designed for balancing trowel machine blades.

- Follow the manufacturer’s instructions to place the blades on the balancer and find if any adjustments are required.

- Balancing the blades ensures equal weight distribution and reduces vibration during operation.

Adjusting or replacing blades as necessary:

- Make necessary adjustments to individual blades by adding or removing weight if they are not balanced.

- If the blades cannot be properly balanced, consider replacing them with new, properly weighted blades.

- Ensure that all blades are securely fastened to the trowel machine before proceeding.

Checking the float pan

Inspecting the float pan for any damage or warping:

- Carefully inspect the float pan, which is the flat surface attached to the trowel machine that helps in creating a smoother finish.

- Look for any signs of damage, such as cracks, dents, or warping, that can affect the pan’s performance and balance.

Adjusting or replacing the float pan as necessary:

- If the float pan is damaged or warped, adjust it using the appropriate mechanisms provided by the trowel machine.

- If the damage is severe or cannot be corrected, consider replacing the float pan with a new one.

Ensuring the float pan is securely attached to the trowel machine:

- Check that the float pan is properly attached and securely fastened to the trowel machine.

- Loose or improperly attached float pans can cause imbalance and affect the overall performance.

Testing the balance

Reconnecting power and starting the trowel machine:

- Once all adjustments and inspections are completed, reconnect the power source to the trowel machine.

- Start the machine according to the manufacturer’s instructions.

Observing the machine’s operation for signs of imbalance:

- Observe the trowel machine during operation to identify any signs of imbalance, such as excessive vibration or uneven blade performance.

- Pay attention to the smoothness and levelness of the concrete finish.

Making further adjustments if needed:

- If there are still indications of imbalance, make further adjustments based on the observed performance.

- Fine-tune the blade balance, pitch angle, or other relevant settings to achieve optimal balance and performance.

Maintenance and Regular Inspections

Importance of regular maintenance

- Regular maintenance is crucial for ensuring the optimal performance, longevity, and safety of trowel machines.

- It helps prevent major breakdowns, reduces the risk of accidents, and prolongs the lifespan of the equipment.

- Proper maintenance also ensures that the machine remains balanced and in good working condition.

Recommended maintenance schedule

- Follow the manufacturer’s recommendations for the specific maintenance schedule of your trowel machine.

- Typically, maintenance tasks may include regular lubrication, checking fluid levels, inspecting belts and filters, and verifying proper functioning of engine components.

Conducting regular inspections for balance and wear

- Regular inspections should be carried out to assess the balance and condition of the trowel machine.

- Check for signs of wear and tear, such as worn blades, damaged float pans, loose components, or any other issues that may affect the machine’s balance and performance.

Conclusions

In conclusion, balancing a trowel machine is vital for achieving smooth and level concrete finishes in construction projects. By adjusting the pitch angle, balancing the blades, and checking the float pan, civil engineers can ensure optimal performance and safety.

Maintaining a balanced trowel machine reduces operator fatigue, enhances the longevity of the equipment, and contributes to the overall quality of the construction work. It is essential to follow the outlined steps and adhere to regular maintenance and inspections to maximize the trowel machine’s performance.

By prioritizing balance and maintenance, civil engineers can elevate their construction projects and deliver exceptional results.

Sources:

Leave A Comment