7 Things To Consider Before Backfill A Foundation

During the construction, foundation is found at the bottom of the structure that receives the load distributed from different structural elements considering that its weight over the area of soil does not exceed the ultimate bearing capacity of the soil underneath and that the settlement over time is within tolerable limits.

The purpose of foundation aside from distributing the weight of the structure evenly over the large area of soil are to increase the stability of the structure, resists or prevents any soil movement effect which avoids unequal settlement and to provide a level surface for the structure.

To design a foundation, there are factors that you should consider and must not ignore to ensure the performance of the foundation or not bear any problems in the future.

- Footing depth or spacing

- Type of soil (sand & slit)

- Water table fluctuation

- Soil Settlement

These are the basic requirement to know that will make sure that it can support all kind of loadings it will bear as designed. In this section, we will be discussing other important and practical matters in foundation design.

tamping rammer start from $150

Contents

What Does It Mean To Backfill A Foundation

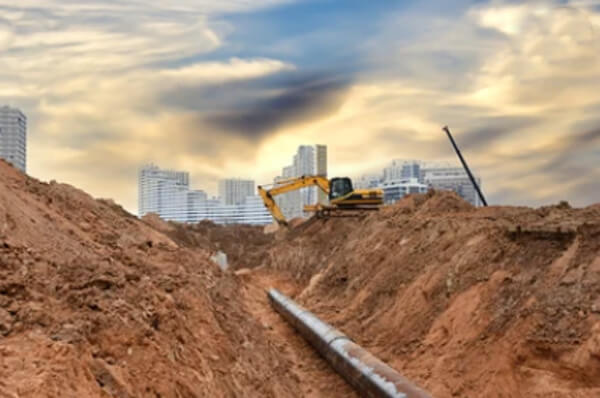

The construction process begins with the excavation, a lot of digging works depending on how big the structure is. The excavated soil are then set aside to be used on the later stage. These are stockpiled and secured that no foreign elements will affect it.

Alongside with the ground works, the excavated material will be tested to determine the actual soil type and properties which will determine if it can be used or placed back or if not, another soil to be used in backfill will be necessary to match with the structural requirement.

The factors that affect your backfill material are:

- Choosing the suitable backfill material

- Compacting the suitable backfill material and

- The time it takes to backfill the area.

Backfilling a foundation is an important process to help protect the structural element. To ensure that the backfill material is right make sure to check if the material sample passed the testing or is approved, required density is achieved and that it is done in layers.

How Long Should Foundation Cure Before Backfilling

After the concreting works, there are things that needs to consider before proceeding with the backfilling. One of which is if the load of the backfill material exerts or imposes heavy loading or force towards the foundation.

The backfill material should not significantly affect or cause the structural deterioration or cracks on the foundation. Though some contractors would not necessary wait for 28 days to achieve the foundation’s full design strength or complete hardness, it is safe to wait up to a week or at least 75% of the strength is fulfilled, considering that it is within ideal site temperature condition.

Curing of the foundation is an essential process and should not be hurried for the backfilling process as it imposes and a controlling factor whether the structure will be in its designed stability.

rammer compactor start from $150

Backfill Foundation Material (Sand, Gravel, Clay, Stone, Topsoil)

Aside from the backfill timing, backfill material is also as important. Backfill material can be classified grade of which the most common examples are sand, gravel, clay stone and topsoil. These material will be decided according to the design requirement of the backfill material to support the structure.

- Coarse-grade Soils

These are gravelly and sandy type of soil and ranges from clayey sands to high quality gravel-sand mixture. Coarse-grade soil are the most popular because it has high quality properties and exhibits slight to no plasticity. These type of soil are easy to compact and provides a good support for the foundation.

- Fine-grade Soils

These are the organic clays, fine sands, inorganic slits. These materials have a property of low to medium plasticity. They are relatively impervious and can be compacted fairly using a heavy duty compaction material and is considered as a good stable backfill.

- Rocks

Rocks can be suitable as a backfill material considering its hardness and gradation. Since rocks are bigger in sizes, before using as a backfill material, hard rocks will undergo a crusher process to ensure that it passes the requirement as a cohesion less material.

To ensure that it passes the design requirement, the bearing capacity of the backfill material should be determined. The sample will undergo field test to determine if it is applicable to be used as a backfill material.

What Is The Best Material To Backfill A Foundation

The best material to backfill a foundation depends on the location of the structure. But the most popular material that achieves the design requirement of a backfill material are the coarse-grade soils. This type of soil is a mixture of gravel, sandy soil and relatively fine material.

It has high quality properties and exhibits slight to no plasticity. These type of soil are easy to compact and provides a good support for the foundation.

How Much Does It Cost To Backfill A Foundation

There is no actual cost that will determine how much money will be necessary to backfill a foundation but what we can share to you is how to compute the cost required for the area to backfilled.

- Type of backfill material and the source of the backfill material (transportation, storage, handling and labor const should be consider if away from the site)

- Series of testing to be done to determine the bearing capacity of the backfill material sample (usually done by a third party laboratory)

- Equipment used for excavation, backfilling and compaction (wherein compaction should be done in layers). Some of the equipment used for compactions are rollers and plate vibrators.

Should Backfill Be Compacted

It is necessary and required to compact your backfill material. Soil compaction is the process of applying pressure and/or vibration to lessen the voids between the particles which results to an increase of soil density. This process results to improvement of soil properties like:

- increases the shear strength and load bearing capacity;

- increases the soil slope stability;

- lessen the void ration which means lesser water seepage and

- increases the stiffness which lessens the settlement during working load.

How To Backfill A Foundation

Initially, foundation should be cured as required before proceeding with the backfill process. The ground which will be filling with the soil material should be free from foreign material like loose stones, dirt and even ponding of water.

Make sure that the surface is clean and corrective measure should be done. Once the suitable backfill material is selected and passed the necessary testing, begin pouring the backfill material at the corners and make sure that the backfill material is evenly distributed along the sides in consecutive layers of 15 to 20 cm of each layer.

Each layer should be compacted and watered. Repeat the procedure until the entire area is completely filled with backfill material. Lastly, further compact the material and water them as necessary.

jumping jack tamp start from $150

Conclusion

To make sure that backfill material is in high quality, backfill transported should be inspected well and should be consistent and uniform in characteristics and are free from foreign elements that can badly affect the stability of the backfill material.

Thorough inspection should be done. Another thing to consider is the proper compaction of the backfill material to prevent a significant settlement of the structure over time that will damage the structural stability and danger the occupant of the structure.

Leave A Comment