5 Powerful Alternatives to Roller Compactor – Pros & Cons

Roller compactors are an essential element of mechanization in the construction industry. These are heavy equipment used to compact soils and other construction materials to required densities. Roller compactors comprise of a weighted drum attached to a frame and pushed or pulled by an engine. Roller compactors are applied in road and building construction for several purposes. In roads, they are used to compact subbase and base layers for sufficient density. This increases the material bearing capacity to sustain designed traffic loads.

Additionally, compaction eliminates air from the material preventing cracking and portholes formation in roads. In building construction, roller compactors are used to stabilize soils for foundation construction. Stabilized soils offer adequate bearing capacity for intended structural loads.

While roller compactors are essential in construction, they could be unsuitable in some occasions. This article explores alternative compaction equipment. The article takes an in-depth look at equipment types, their pros, and cons when used in place of roller compactors.

Contents

Alternatives to Roller Compactors

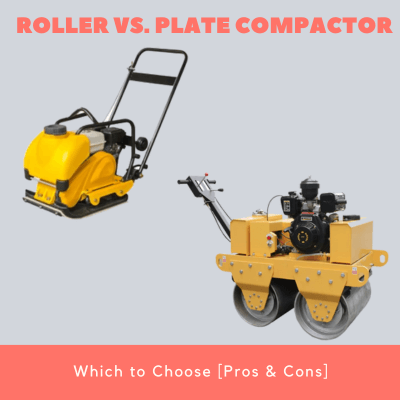

A. Vibratory Plate Compactors

1. How vibratory plate compactors work

A vibratory plate compactor consists of a heavy base plate that exerts downward force. An eccentric rotating shaft, powered by an engine, creates vibratory motion. This transfers vertical forces to the ground, compacting soil the material. The base plate’s shape and weight distribution optimize compaction.

2. Advantages and disadvantages compared to roller compactors

Vibratory plate compactors offer portability and maneuverability, ideal for tight spaces and smaller projects. However, their limited compaction depth and slower speed can be limiting for larger areas. In contrast, roller compactors cover larger areas swiftly, with greater compaction depth and efficiency, suitable for larger-scale projects. Yet, they may struggle with tight spaces.

3. Suitable applications for vibratory plate compactors

Vibratory plate compactors are well-suited for compacting granular materials like gravel, sand, and crushed stone. The high-frequency vibrations penetrate and consolidate these materials, increasing their density and stability for construction and landscaping applications.

B. Hand Tampers

1. Hand tampers and their manual operation

Hand tampers are manual compaction tools used for smaller areas. They consist of a heavy metal base and a long handle. To operate, an operator lifts the tamper and strikes the ground repeatedly, transferring energy to compact soil.

2. Pros and cons in relation to roller compactors

Hand rammers offer portability and precision, allowing compaction in tight spaces and around obstacles. They are cost-effective and require minimal maintenance. However, they are labor-intensive and slow for larger areas. Roller compactors, in contrast, cover larger surfaces quickly and offer consistent compaction. They require fewer operators but might struggle in confined spaces. Roller compactor costs and maintenance are higher.

3. Projects where hand tampers are effective

Hand tampers are effective for projects like compacting small trenches for utility lines, backfilling around posts or foundations, and landscaping tasks like compacting soil around plants or creating small paths. Their portability and precision make them suitable for confined areas where larger equipment can’t reach.

C. Pneumatic Compactors

1. Pneumatic compactors and their functioning

Pneumatic rollers are equipped with air-filled rubber tires. These rollers compact materials like asphalt during road construction. Air pressure in the tires can be adjusted to control compaction force. The weight of the machine combined with the kneading effect of the tires achieves uniform compaction and smooth surfaces, suitable for road and pavement projects.

2. Contrast with roller compactors, highlighting differences

Pneumatic rollers use rubber tires filled with air to apply even pressure and kneading action, suitable for finishing asphalt surfaces and delicate soils. Roller compactors employ the steel drum’s weight and an eccentric rotating shaft to generate dynamic forces, ideal for densifying granular materials and cohesive soils. Pneumatic rollers offer precise compaction with less vibration, while static and vibratory compactors provide higher compaction rates but with more ground disturbance.

3. Types of surfaces and materials pneumatic compactors are best suited for

Pneumatic rollers are effective for compacting materials like asphalt, both hot mix and cold mix, due to their rubber tires that provide gentle yet consistent pressure. They are also suitable for cohesive soils, like clay, and granular materials, such as gravel and crushed stone. The adjustable tire pressure allows versatility in achieving optimal compaction for various materials.

D. Sheepsfoot Rollers

1. Sheepsfoot rollers and their unique design

Sheepsfoot rollers feature a drum equipped with rectangular or oval protrusions resembling sheep’s feet. These protrusions, known as “feet,” penetrate and knead the soil as the roller moves, effectively compacting cohesive soils.

2. Advantages and limitations when compared to standard rollers

Sheepsfoot rollers offer advantages in compacting cohesive soils like clay due to their kneading action that minimizes air voids, improving soil density. However, they are less effective for granular materials. Standard smooth drum rollers are versatile, suitable for both cohesive and granular soils, providing a smoother finish. They lack the aggressive compaction of sheepsfoot rollers in cohesive soils but excel on less challenging terrains.

3. Situations where sheepsfoot rollers excel

Sheepsfoot rollers excel in compacting cohesive soils with high moisture content, such as clay and silt. Their unique design, featuring protruding feet on the drum, effectively kneads and compacts these challenging materials, reducing air voids and increasing soil density. This makes them particularly suitable for projects like dam construction, earthworks in clay-rich areas, and creating stable foundations in areas with challenging soil conditions.

E. Vibratory Rollers

1. Introduction to vibratory rollers and their mechanics

A vibratory roller relies on the weight of the drum and vibrations for compacting materials. Its vibration mechanism comprises eccentric weights attached inside the roller drum. When triggered, the weights undergo a high frequency oscillation generating vibrations that transfer to the drum and subsequently to the ground. These vibrations break down air voids, enhancing compaction efficiency and soil density for construction projects.

2. Comparing vibratory rollers with traditional roller compactors

Vibratory rollers use dynamic vibrations generated by an eccentric shaft to enhance compaction efficiency, making them highly effective for granular materials and cohesive soils. Traditional rollers, on the other hand, rely solely on static weight for compaction and are more suitable for cohesive soils. Vibratory rollers offer faster compaction and better density, while traditional rollers provide smoother finishes.

3. Specific projects that benefit from vibratory rollers

Vibratory rollers are ideal for a range of projects, including road construction, highway maintenance, and airport runway compaction. They excel in compacting granular materials like gravel and crushed stone, as well as cohesive soils such as clay. Their dynamic vibration mechanism increases compaction efficiency, ensuring stable and durable surfaces.

Factors to Consider When Choosing an Alternative

A. Type of Material

Cohesive soils like clay require machines like sheepsfoot rollers for kneading action, while granular materials demand vibratory rollers to break down air voids. Choosing based on material ensures optimal compaction, preventing inefficiencies or damage during construction projects.

B. Project Scale and Scope

Smaller projects with confined spaces might favor hand tampers for precision, while larger projects could benefit from the efficiency of vibratory or pneumatic rollers. The choice should align with the project’s size, space constraints, and required compaction rates for optimal results.

C. Surface Type and Conditions

In uneven or hilly terrains, lighter and more agile equipment might be preferable, while on smoother surfaces, heavier machinery can be used. Soil characteristics, whether cohesive or granular, also influence the choice to ensure optimal compaction performance and project success.

D. Accessibility and Space Constraints

For confined or hard-to-reach areas, compact equipment like hand tampers or plate compactors may be suitable. These options maneuver efficiently in tight spaces, ensuring effective compaction in locations where larger machinery like roller compactors might face challenges.

E. Cost and Budget

Factors like equipment purchase or rental costs, maintenance expenses, fuel consumption, and labor requirements must be assessed. The chosen option should align with the project’s financial constraints while ensuring effective compaction and meeting construction quality standards.

Case Studies

A. Projects where alternatives were used successfully

In a landfill expansion project, pneumatic-tired rollers were used to compact geomembrane liners, preventing damage and ensuring proper containment of waste.

In a pipeline project, vibratory plate compactors were employed to stabilize the soil beneath the pipeline.

A road rehabilitation project utilized rubber-tire rollers to compact asphalt overlays.

B. Outcomes and lessons learned from employing alternatives

In landfill expansion, the rollers’ gentle yet effective compaction minimized liner punctures while adhering to environmental regulations.

In the pipeline project, the compactors efficiently densified the soil, enhancing load-bearing capacity and preventing future settling, reducing maintenance costs.

In road rehabilitation, the rollers’ flexibility and adjustable tire pressures optimized compaction and achieved uniform surface finishes, extending the lifespan of the pavement while minimizing disruption to traffic.

C. Project-specific considerations that influenced the choice of alternative

In the geomembrane landfill case, the project focused on preventing liner damage and adhering to environmental standards, leading to the choice of pneumatic-tired rollers for gentle compaction. Soil stabilization for the pipeline prioritized enhancing load-bearing capacity, prompting the use of vibratory plate compactors. The road rehabilitation aimed for optimal pavement quality and minimal traffic disruption, favoring rubber-tire rollers’ versatility and precision.

Conclusions

There are several alternatives to roller compactors; these include hand tampers, sheepsfoot rollers, vibratory rollers, vibratory plate compactors, and pneumatic rollers. The choice of an alternative depends on project requirements and material considerations.

Having the right compactor for a project ensures efficient compaction and project sustainability. Carefully evaluating the project requirements and making the right decision on the alternative compactor ensures project success.

Leave A Comment