6 Things You Need to Know About Mortar Spraying

Mortar is a binding material used in construction, particularly in masonry industry, to fill in the gaps between different building blocks like bricks, stones, etc… Mortar can also be used for decorative patterns in the brick industry.

Mortar is produced by combining cementing material like lime, cement or combination with fine aggregates like sand which will then be well incorporated by adding water.

Mortar can be of different types, of which there are four (4) common types: cement mortar; mud mortar, lime mortar and special mortar.

Cement mortar is created by mixing the basic components which are the Portland cement, sand and water. Cement mortar is used for masonry blocks and gives a smooth finish to wall and other concrete surfaces.

Mud mortar is made by adding sand, clay and water. They are cheap but less durable compared with other type. Mud mortar are usually found in houses. Lime mortar are made from lime, sand and water and are usually non hydraulic and sets very slow through reaction with carbon dioxide in air.

Lastly is the special mortar which are used to make the building blocks stronger are more durable.

Mortar now can be quickly applied due to the mechanization of the process. These are the commonly asked questions regarding the mechanized way of mortar application.

Contents

Can Mortar Be Sprayed

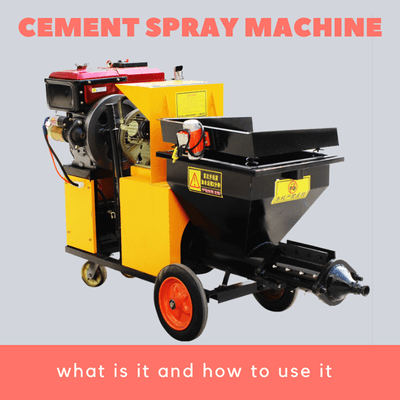

Due to the advancement of the technology, mortar application can be done through a spraying machine. The mortar spraying machine is fabricated to do a mortar application with lesser time consumed and lesser labor required.

This user-friendly machine can achieve a better mortar application once the process before spraying is being followed. One of the most important process is the mixture.

The mixture between the cement, fine aggregates and water should be as per designed to achieve the quality and strength of the cured mortar. The spray mortar can be of dry and wet mixtures.

Dry Spray Mortar Mixture

The dry mortar mixture is using a predetermined ratio of concrete and aggregate, depending of the strength it should achieve, without mixing it to water. The dry mixture will be fed into the machine and is pressurized with high velocity airstream that will be conveyed on the hose to the spraying nozzle.

In the spraying nozzle area, the atomized spray arrangement of water is found for the purpose of hydrating the cement mixture. Just like achieving the right ratio of dry mixture between cement and aggregate, the right amount of water will be sprayed consistently to achieve the right compressive strength.

Wet Spray Mortar Mixture

The wet mortar mixture is by using a batch of a mixture of water, cement and aggregates. This mixture can be of readily mixed or are being mixed on site. The batch of the mixture should be done before feeding in to the machine especially for larger concrete spraying application.

The mixture will be then feed, wherein the water-cement ratio be controlled depending on the strength to achieve, and a high velocity air is applied in order for it to pass through the hose to the nozzle.

How Do You Use a Mortar Sprayer

For both dry mixture, the material will be fed into the hopper or the mixture if not pre-mixed. The mixture should be well mixed before being transferred to a distributor into a stream of compressed air in a hose towards the nozzle. The pressurized water will be then sprayed after to finish the mortar application.

For the wet mixture, it involves with feeding the pre-mixed or the prepared mortar and pump it towards the nozzle. Adjust the sprayer into the consistency of the material.

Make sure that the plaster material is in the right consistency to achieve the right finish of the surface. After these steps, align the nozzle to its working condition and do a test spray to make sure that everything is working fine and that the consistency and volume of plaster is right before spraying it to the work surface.

Now that you’ve tested the sprayed plaster, spray it to the work surface in even rows with a consistent distance away from the surface.

How Thick Can You Spray Mortar

Depending on how big your machine or spray is, the thickness is 1/8 inch to 1 inch for structural layers. In order to establish the effectiveness of the mortar, the quantity and quality of the mixture is very important.

For dry mixture, it has a lower water to cement ratio wherein no pumps are needed since the water will be added after the dry mixture is being sprayed. Aside from the mixture, an experienced nozzle man is required in order to achieve the right amount of water added.

For the wet mixture, it has a higher water to cement ratio and during the mixing of, the precise and right amount of water should be added. Another aspect to be considered is how big the batch is and the time it will be sprayed as it may need a retarder.

How Do You Make Mortar Stick Better

To make the mortar stick better, you should consider using a high-quality mortar and use the right amount of water depending on the required strength upon curing.

The nozzle man should also know how to use the mortar spraying machine and that these rules should be followed:

(1) Proper cleaning of the surface before spraying

(2) Able to apply bonding coating before heavier shotcrete application

(3) Proper distance of the nozzle and the surface to achieve the right consistency and thickness of the shotcrete layer

(4) Lessen the bulging, air pockets, sagging and rebounds

(5) Lastly, clean the equipment immediately after application to prevent accumulation of the materials in the pump, hose and nozzle which will after the succeeding application.

Can You Spray Mortar With a Hopper

A hopper is where the dry mixture are being fed where the mixture are to be mixed properly before it goes to the machine wherein afterwards, the compressed air will push the mixture, whether dry or wet, to the nozzle directing it to the surface.

How Long Does It Take For Rapid Set Mortar to Cure

Rapid set mortar is used to reduce the waiting time before proceeding to the next proceeding to the next procedure. Depending on the quality and weather, the rapid mortar can initially set in more or less 20 minutes and have its final setting for more or less 35 minutes.

The rapid set mortar can start achieving its strength in one hour and achieve its design strength in 28 days.

Conclusion

The mechanizing of the mortar application is to quicken the process with lesser labor required but the consistency of the mortar still depends on the mixture’s ratio and the experience of the nozzle man.

With these things being considered, the mortar mix will have a better smoothness or evenness compared with the result using the conventional method. The mixture should be in the right ratio because if it is too dry, the mixture will not stick to the surface and if it is too wet, you will create a runny mixture which will overflow between the gaps and produce waste.

After knowing these things during the application, maintenance of the spraying machine should always be done to ensure that the machine can give a good result and not waste mortar material.

Leave A Comment