Jumping Jack Compactor: What’s it and How to Use [Steps&Tips]

While using a jumping jack, plate compactor, or tamping rammer it is very important to understand the goals behind.

Soil compaction is the process of removal of air and water from the soil, which results in increased dry density. Whether it is a building, dike, or sidewalk, soil compaction ensures stability.

A poorly compacted soil or foundation might lead to cracks and endanger lives. Jumping Jack Compactor is one of the many machines available that efficiently carry out compaction of the soil.

Investing in the right compacting machine can make your life much easier at the construction site.

This article will give you deep insight into the use, properties, and working of jumping jack compactors.

Contents

What is a Jumping Jack Compactor?

Jumping Jack Compactor, also called rammer or jumping jack tamper, which is a machine used for compacting ground. It applies consecutive impacts on the ground to level the uneven surface, thus increasing the dry density of the soil. The compaction process removes air and water from the soil.

While most compactors use vibration, a jumping jack compactor uses the impact force to compress the soil. The foot of the machine lifts from the ground and slams back down which results in deeper compaction depths.

Jumping Jack Compactors can be used for various soil types but are ideal for cohesive soil compaction with a 13% moisture range. Their cramped size makes them perfect to use in hard-to-reach places like trenches and ditches. With the latest design features, jumping jack compactors can easily be navigated by a single operator without any difficulties.

jumping jack vs plate compactor

Structure Overview

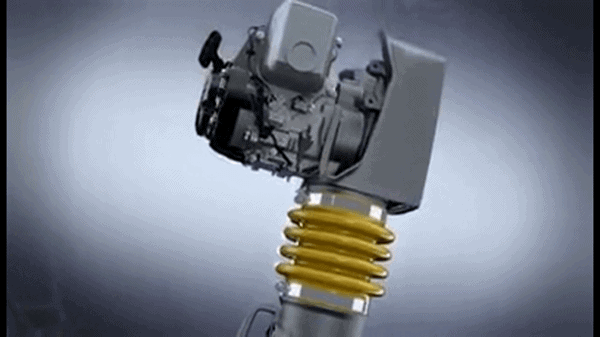

The upper body of rammer is where the centre of gravity is located and consists of an engine part, slowdown machine part, guide portion with handle, and a fuel tank that is connected to the shock absorber.

The lower body of the machine has spring part covered with foot case and the anteverted part that moves the body forward.

plate compactor or jumping jack

Specifications Overview

There are several models available with unique features in jumping jack compactors which can be chosen according to the job. On average they are designed to provide 700-800 blows per minute and apply a pressure of 0.17 MPa on the ground. These rammers have an operating weight of 60kgs – 80 Kgs

How is it working

An air-cooled engine is installed to supply power to the machine. Once the machine is started the transmission of power takes place by engaging the centrifugal clutch. The speed of rammer is changed using gears which changes the rotational motion to vertical thrusts. When the lower plate of the machine receives power, it performs a continuous up and down movement with impact force thus, compacting the soil.

How to Use It

- Jumping Jack Compactors have an oil-based lubrication system hence, it is very important to replenish oils before starting the machine. Fill gasoline till the marked level, on failing to do so the engine seizures may occur during the operation.

- The fuel cock lever must be pulled down to start the machine. Followed by switching the power ‘ON’.

- Close the carburettor choke lever and open the throttle lever. Pay special attention to the weather conditions before using jumping jack operators. On cold days, ignite the engine to warm it up before operating. In hot days it is advised to leave the throttle lever half-open to cool it up.

- To start the ramming, quickly move the throttle lever from ‘close’ to ‘fully open’ position.

- Once the tamping action is started, adjust the jumping position according to the soil type by controlling to throttle lever.

- Use the rammer in the erect position and manoeuvre with handle.

- Once the allocated area is compacted turn off the machine by quickly pulling the throttle lever from ‘ON’ to ‘OFF’ position. Let the engine cool for 3-5 minutes before switching off the main power supply. In the end, close the fuel cock.

For more videos,please go to our YouTube Channel

Tips for Using Jumping Jack Compactor

- Jumping rammers are designed to be used for cohesive soil like clay. Avoid using rammers on gravel & on asphalt, as they might create a hole instead of compacting or even worse, damage the machine.

- Jumping jack compactors provide direct compaction to particular spots which makes them ideal for tight spots and trenches. Incorporating them into smaller projects can lead to faster completion and higher efficiency.

- It is always recommended to check every bolt and screw in the machine before using it. Constant vibration may cause the screws to loosen up which might lead to an unwanted disaster.

- Always be attentive while using jumping rammers. They require a lot of strength and attention while handling but the results are top-notch.

- Remove the dirt and dust from the engine and handle regularly for prolonged machine service.

Jumping Jack Compactors have enhanced the process of compaction of soil by making it convenient and efficient. This easy-to-use machine can give great results in much less cost, manpower, and time.

More Articles May You Inetrested

Leave A Comment