Choose the Right Size Rebar: Top Tips for Concrete Slabs

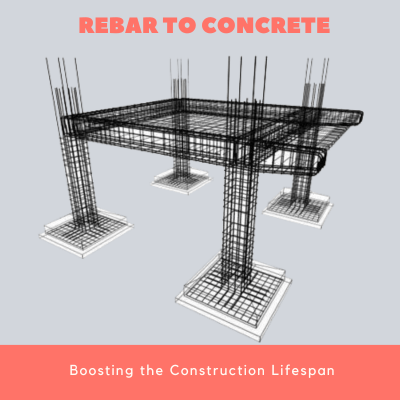

Reinforced concrete slabs are the norm for providing robust and durable floors and ceilings in modern commercial/ residential buildings, skyscrapers, and bridge decks, because they allow builders to create longer and thinner spans without intermediate supports while reducing the risk of structural failures caused by earthquakes, higher wind speeds or other natural disasters.

Steel reinforcement bars have made these far-reaching changes possible, as plain concrete does not do well against tensile stresses. When rebar is installed in concrete, it forges a composite material. The concrete safeguards against compressive stress, and the rebar shields against tensile stress, enhancing the structural strength of the project.

Contents

Rebar in Concrete Slabs

Concrete is a composite material made from cement, water, aggregates (sand or gravel), and even admixtures to make it even better for specific situations. It’s a complex beast that displays both strengths and weaknesses.

Strengths and Weaknesses of Concrete

Concrete has shaped our world from sidewalks to skyscrapers, culverts to bridges, canals to dams. The widespread use of concrete underscores its versatility as it is a user-friendly and durable building material. However, the only chink in its armor is that single-handedly concrete cannot deal with tensile stress as it is incredibly brittle.

Concrete is a complex beast exhibiting both strengths and weaknesses:

Strengths | Weaknesses |

| ➔ High compressive strength ➔ Durable ➔ Fire-resistant ➔ Low maintenance ➔ Versatile | ➔ Low tensile strength ➔ Brittle ➔ Porous ➔ Shrinks over time ➔ Susceptible to chemical damage ➔ Poor strain capacity |

To overcome weaknesses, we first need to understand the different types of stress that can be placed on objects.

Types of Stress: Compressive, Shear, and Tensile

Compressive stress

Compressive stress is exerted on an object when a force tends to shorten it; just like when you stand on a soda can, the weight of your body flattens it.

Shear stress

Shear stress kicks in when forces strive to deform a body by sliding its internal layers past one another. When you try to tear a piece of paper, it undergoes shear stress owing to pushing layers in opposite directions.

Tensile stress

Tensile stress seeks to pull an object like an internal tug of war that lengthens or stretches that material. When you pull a rubber band, the force stretching it is tensile stress, causing it to expand and become longer and thinner.

Concrete is firm under compressive stress but is fragile and susceptible to cracking when subjected to varied forces. Plain concrete has inadequate strain capacity and tensile strength, accounting for only 10-15% of its compressive strength, adversely impacting structures’ life span.

Concrete’s Poor Tensile Strength

Rebars enhance concrete’s tensile strength, stability, and longevity, enabling the composite material to endure more stress and strain because the reinforcement distributes and diffuses tensile stresses. This combination makes it possible to erect durable, long-lasting structures such as skyscrapers and bridges that can withstand diverse loads and environmental factors.

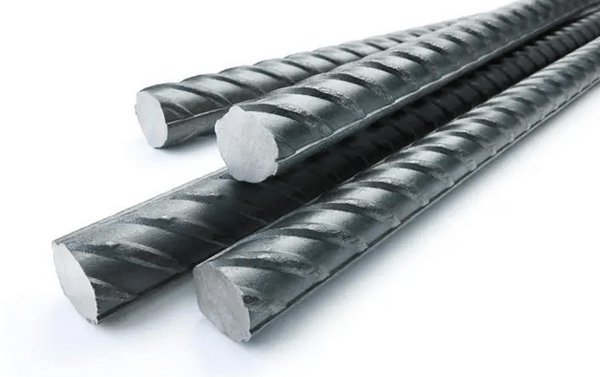

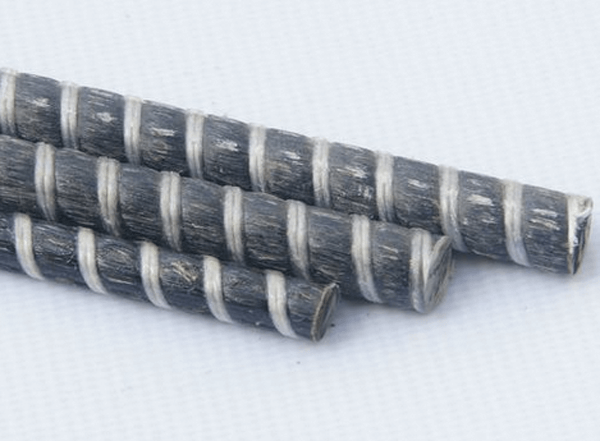

Types of Rebar Materials

Rebar comes in two distinct types: steel and fiberglass. Steel rebar is manufactured from carbon steel and has ridges or ribs, permitting adequate bonding with concrete. GFRP, or glass fiber-reinforced polymer rebar, is produced when the polymer matrix is blended with glass fibers to fortify the product as a whole.

While there are other options, carbon steel bars remain the most widely used method to reinforce concrete. Environmental factors such as moisture and salt in marine environments dictate the choice of the most suitable variant. Let’s take a look at these different types of carbon steel variations:

Carbon Steel Rebar

Carbon steel is the most common type of rebar used in residential and commercial projects. This alloy steel is exceptionally cost-effective and durable; however, using carbon steel rebars may be risky if you work with high moisture content or in high-humidity areas.

| Pros | Cons |

| ★ High bearing capacity ★ Great tensile strength ★ Bendable and versatile ★ Lower carbon content is more weldable | ★ Susceptible to corrosion ★ Heavy |

Galvanized Rebar

Galvanized rebar is the material that results after steel rods or wires are hot-dipped into zinc to create a protective coating. This coating protects the steel from the elements, making it stronger and more erosion-resistant, adapting it to be used in reinforced concrete in more aggressive environments.

While galvanized rebar offers some advantages, it has drawbacks, like higher cost and the potential for chipping of the epoxy coating during installation.

| Pros | Cons |

| ★ Same tensile strength as carbon steel rebar ★ More resistant to corrosion than carbon steel ★ Equal bearing strength to other tempered steel rebars ★ The zinc coating withstands shipping and installation better than other coatings. | ★ The galvanized coating can crack, chip, or flake ★ More expensive than some other options |

Stainless Steel Rebar

Stainless steel is formed by adding chromium to the extent of 10.5% or more in carbon steel. Stainless steel rebar offers a good combination of high strength, toughness, flexibility, and corrosion- resistance. It is used for constructing bridges and other structures in areas of high seismicity.

Stainless steel rebar is expensive and considerably increases the cost of structure.

| Pros | Cons |

| ★ Multi-purpose and ductile ★ Enhanced structural durability ★ Lower upkeep and maintenance costs ★ Same bearing and tensile strength as carbon steel | ★ High initial cost ★ Difficult to find |

Epoxy-Coated Steel Rebar

Epoxy-coated steel rebar, as the name signifies, has a layer of epoxy resin applied to its surface. The epoxy coating protects the steel against moisture, chlorides, and other hazardous substances, extending the life span of structures where the rebar will be exposed to extreme circumstances, such as bridges and marine structures.

Epoxy-coated rebar is a more expensive option than carbon steel rebar and epoxy coating might be fractured during handling or installation, reducing its effectiveness.

| Pros | Cons |

| ★ Superior Corrosion Resistance | ★ Higher Cost ★ Epoxy coating gets scratched or damaged during handling or installation |

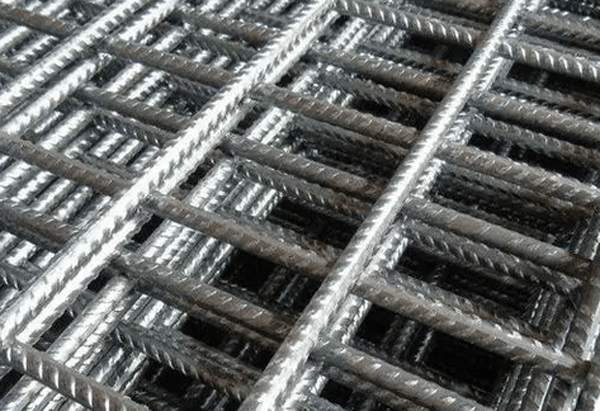

Welded Wire Fabric

Welded wire mesh is a series of welded wires where the individual wires cross. For diverse applications, welded wire fabric is crafted from mild, galvanized, or even stainless steel.

Beyond its core use in reinforcing concrete and retaining walls, welded wire fabric has applications in diverse areas like fencing, security screens, and storage solutions.

Welded Wire Fabric is rigid in form and thus is more complex and costlier to set up on stepped or sloped areas.

| Pros | Cons |

| ★ Budget-friendly | ★ Limited strength |

| ★ Easy to handle | ★ Spacing limitations |

| ★ Fast installation | ★ Susceptible to corrosion |

| ★ Good for less demanding applications |

Choosing the Right Size of Rebar

Selecting suitable rebar size and grade requires careful engineering calculations to provide adequate reinforcement and ensure that structures are reliable and affordable.

Rebar sizing and the significance of the numbering system

Steel rebars are available in distinct sizes, grades, and variations to support diverse constructions. Standard rebar sizes vary across regions, but metric and imperial sizes are prevalent.

The array of diameters of the imperial bar are listed in the table below:

| Bar No. | Dia. (in) | Dia.(mm) | Nominal Weight (lb/ft) | Nominal Weight (kg/m) | Nominal Area (in²) | Nominal Area (mm²) |

| #3 | 0.375 | 9.5 | 0.376 | 0.560 | 0.11 | 71 |

| #4 | 0.500 | 12.7 | 0.668 | 0.994 | 0.20 | 129 |

| #5 | 0.625 | 15.9 | 1.043 | 1.552 | 0.31 | 199 |

| #6 | 0.750 | 19.1 | 1.502 | 2.235 | 0.44 | 284 |

| #7 | 0.875 | 22.2 | 2.044 | 3.042 | 0.60 | 387 |

| #8 | 1.000 | 25.4 | 2.670 | 3.973 | 0.79 | 510 |

Rebar diameters range from #3, the smallest, to #18, the largest

Here are common uses for each steel rebar size:

- #3. This thin, cost-effective mild steel rebar is primarily used in structural members where moderate stress levels are anticipated, such as concrete roads, driveways, patios, and residential structures.

- #4 — Slightly thicker, #4 rebar is a workhorse suitable for reinforcing foundations of houses, buildings, and other structures.

- #5 —The most important applications of this dia. of rebar are bridge decks, foundations for high-rise and industrial structures, retaining walls, and roadway

- #6 —Frequently used in retaining walls, tilt-up walls, and deck-grade

- #7 — Props up massive structures like Multi-story shopping malls and bridges over roads and waterways.

- #8 Provides the muscle behind bridge abutments, sea walls, and high-rise

Select the right size rebar

The size of the rebar depends on the specific requirements of the project, including:

- Load-bearing capacity

- Span and spacing of rebar

- Thickness of the concrete cover

- Type of structure (building, bridge, road, )

Generally, larger rebar sizes (e.g., #8, #9) are used for heavy-load applications, while smaller sizes (e.g., #3, #4) are used for lighter loads. Using the correct size of rebar ensures:

- Adequate tensile strength

- Proper bonding with the concrete

- Sufficient durability

- Compliance with building codes and

Consulting with a structural engineer or referring to relevant building codes and standards (e.g., ACI, ASTM) can help determine the appropriate rebar size for a specific project.

Placement and Application Techniques

Proper placement and application techniques are essential to ensure the effectiveness of rebar.

Placing rebar within concrete slabs

- Maintain consistent

- Secure rebar with wire or tying

- Ensure adequate concrete

- Align the rebar parallel to the longitudinal

- Avoid overlapping

- Use rebar chairs or

- Verify rebar placement before concrete

- Follow design specifications and local building

Specified spacing and depth to ensure durability

Adhering to specified spacing and depth of rebar is crucial to ensure the durability of reinforced concrete structures. Here’s why:

- Structural integrity

- Load distribution

- Concrete cover and corrosion protection

- Bonding between concrete and rebar

- Crack control

- Ductility and safety

- Code Compliance

Common mistakes and how to avoid them

Here are common errors while placing rebar and how to avoid them:

Mistakes

- Inadequate concrete cover

- Incorrect spacing

- Rebar overlap

- Rebar exposure

- Improper tying

- Rebar bending

- Insufficient rebar

- Poor rebar alignment

Avoidance strategies

- Follow design specifications

- Use rebar chairs and supports

- Tie rebar securely

- Keep rebar clean and dry

- Bend rebar carefully

- Use sufficient rebar

- Verify rebar placement

Cutting and Bending Rebar

Cutting and bending rebar requires precision to ensure strict compliance with specifications and engineering plans in reinforced concrete construction to maintain the stability and reliability of the structures.

Tools and techniques for cutting and bending rebar

Cutting Tools

- Rebar cutters (handheld or hydraulic)

- Abrasive wheels (angle grinders or circular saws)

- Bolt cutters (for smaller rebar)

- Shears (for precise cutting)

Cutting Techniques

- Measure and mark rebar accurately before cutting

- Use the appropriate cutting tool for rebar size and type

- Cut rebar at a 45-degree angle to prevent burrs

- Deburr cut ends with a wire brush or grinder

Bending Tools

- Rebar benders (handheld or hydraulic)

- Rebar hooks (for manual bending)

- Rebar bending machines (for precision and high-volume bending)

Bending Techniques

- Measure and mark rebar accurately before bending

- Use the appropriate bending tool for rebar size and type

- Bend rebar to precise angles and configurations

- Use bending templates or guides for accuracy

Safety tips when handling and preparing rebar

Here are some safety tips when handling and preparing rebar:

- Wear protective gear (gloves, safety glasses, steel-toed boots, long sleeves)

- Handle rebar with care (lift carefully, avoid dropping or throwing)

- Cut rebar safely (use appropriate tools, cut away from the body)

- Bend rebar carefully (use appropriate tools, avoid over/under-bending)

- Store rebar properly (off-ground, dry, secure area)

- Use proper lifting techniques (lift with legs, not back)

- Keep work area clean (clear debris and obstructions)

- Use rebar caps or protective covers (cover sharp edges and points)

- Avoid overreaching (use extension tools, ladders)

- Follow manufacturer instructions (read and follow safety guidelines)

Conclusions

The size of rebar you should use for a concrete slab depends on the intended use and the expected load on the concrete slab. A residential slab may have different load considerations than an industrial floor. Heavier loads generally require thicker slabs and larger diameter rebar.

So, how do you pick the ultimate rebar solution for your concrete slab? Consulting with professional structural engineers is your best insurance policy. With their wealth of expertise and experience, they’ll evaluate your project, ensuring the selection of the most economical rebar type and size, complying with building codes and engineering specifications. With their guidance, your concrete slab will be built to last, standing solid and dependable for many years ahead.

Leave A Comment